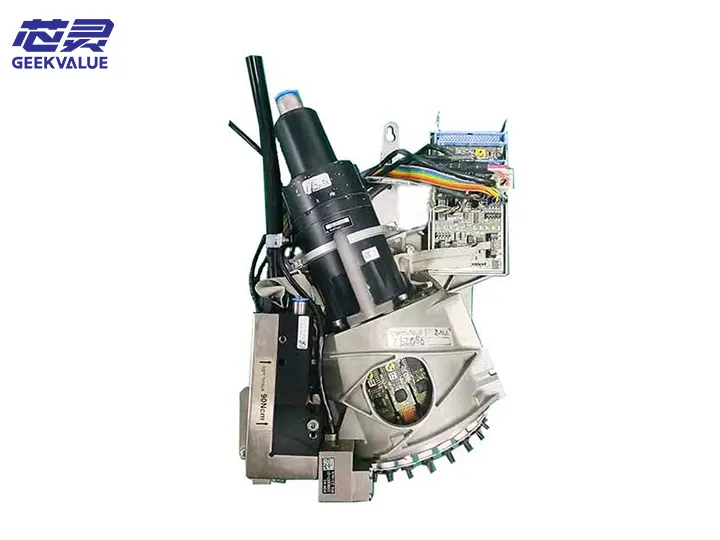

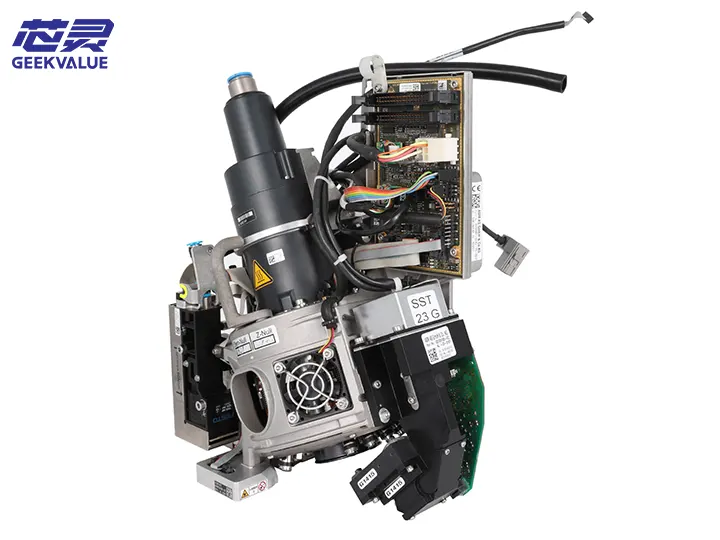

Yamaha SMT YV180XG is a high-speed/ultra-high-speed SMT machine with the following main functions and features:

SMT speed and accuracy: The SMT speed of YV180XG is 38,000CPH (chips per hour) and the SMT accuracy is ±0.05mm.

SMT range and number of feeders: The SMT machine can mount components from 0402 to SOP, SOJ, 84 Pins PLCC, 0.5mm Pitch 25mm QFP, etc., and is equipped with 80 feeders.

PCB size: Applicable to PCB size of L330×W330mm.

Operation steps and precautions

Operation steps:

Check the working status of the SMT machine and the quality of circuit boards and electronic components.

Set the mounting parameters, including mounting position, speed and pressure, etc.

Turn on the power of the placement machine, set the placement program, install the electronic component feeder, place the circuit board on the conveyor, start the placement program and observe the action of the placement head.

Precautions:

Wear protective equipment before operation to ensure that the placement machine is in a stable state.

When replacing electronic components, make sure that the feeder has no current or voltage.

Check the working status of the placement machine at any time to ensure the quality and efficiency of placement.

Clean and maintain before stopping to extend the service life of the machine.

Maintenance and troubleshooting methods

Maintenance: Clean and maintain the placement machine regularly to ensure that it is in the best working condition.

Troubleshooting:

If the placement head is stuck or the placement is inaccurate, check and clean the placement head.

If the electronic component feeding is abnormal, check whether the components in the feeder are blocked or lacking.

If the pad is not firmly pasted, check the cleanliness of the pad and whether the placement pressure is appropriate.

If the placement machine is in an abnormal working state, try to restart or perform system upgrades and calibrations