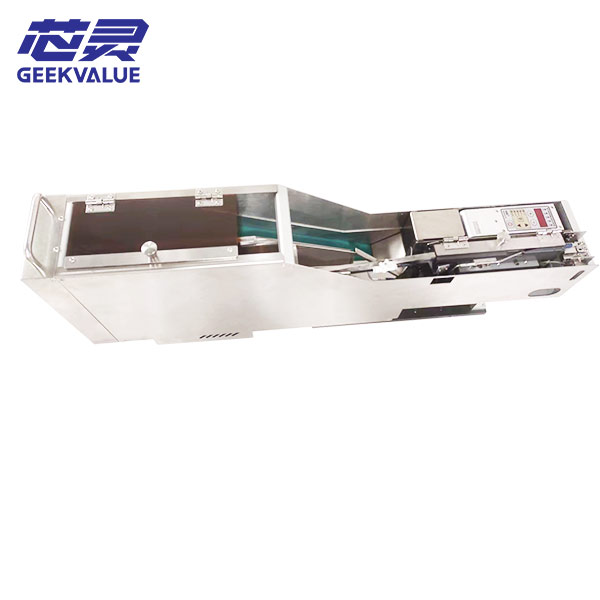

SMT universal error-proof automatic material receiving machine AS0918, automatic material receiving replaces manual material receiving, higher pass rate, improves equipment transfer rate, automatic verification replaces manual verification, no need for manual sampling and measurement, more foolproof, higher efficiency, reduces employee labor intensity, simplifies customer production processes, improves employee work efficiency, reduces management costs, employee turnover, increases automation, does not rely on manual labor, uniform material receiving conditions, controls the risk of wrong materials in the last kilometer, and confirms one second before receiving materials.

Function introduction:

1. Support various tapes of different materials (paper tape, black tape, transparent tape, etc.)

2. The machine automatically adjusts the width to apply to 8mm, 12mm, 16mm or 24mm tapes

3. Support tapes with different spacing (2/4/8/16mm or 20mm)

4. Support tapes of different thicknesses, 0.1mm-1.5mm thickness tapes are compatible

5. Support empty material detection, the minimum supported component is 01005

6. Automatically detect resistance, capacitance, and inductance, automatically check silk screen, and prevent wrong materials

7. Support wireless scanning barcode to check and prevent wrong materials

8. Can be connected to the customer's MES system to form a closed loop with the system to prevent wrong materials

9. Offline machine, can be moved freely

10. Simple interface operation