Fuji SMT machine 3rd generation M3C features include the following aspects:

Lightweight work head: Work head replacement becomes very simple, achieving high-speed and high-precision placement.

Single-sided operation: Shorten the moving distance when replenishing and changing lines, and freely design the production line layout.

Component detection: Check whether the components are upright, missing parts, upside down, and check the three-dimensional coplanarity of defective components.

Low-impact placement: Reduce the impact during placement and protect the components.

Multi-function nozzle: The nozzle size is integrated from 4 to 3 to adapt to components of different sizes.

DX work head: Various components can be placed, including ordinary components, large and special-shaped components, etc.

High productivity: The unit area productivity reaches 67,200 cph/㎡, leading the industry.

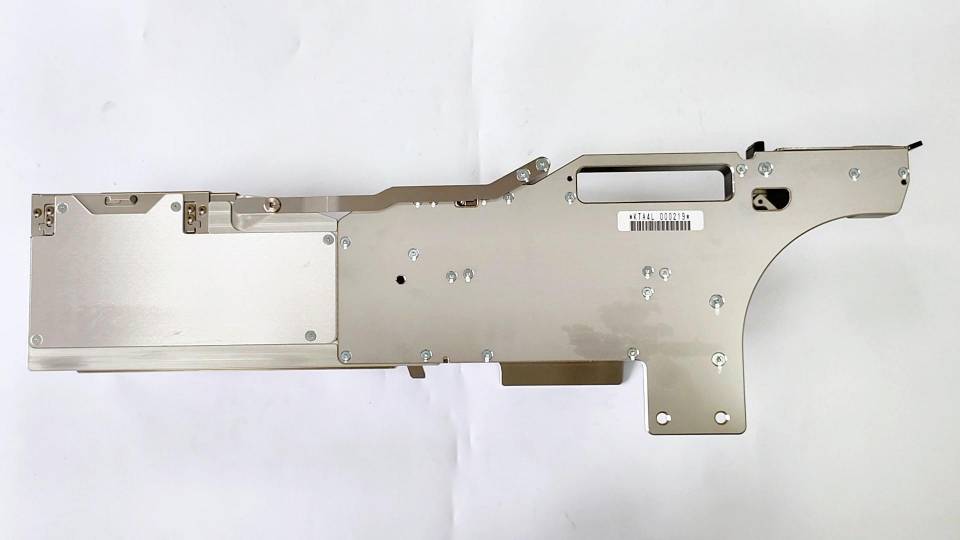

Special process: Complete special processes in the production line to improve production efficiency. Placement range: Suitable for the placement needs of various electronic components, including ordinary components, large and special-shaped components, etc. High-precision placement: Adopting high-precision recognition technology and servo control technology to achieve ±0.025mm placement accuracy. Compatibility: Used with a variety of feeders and tray units to achieve flexible and changeable placement needs. These functions make Fuji M3C, the third generation of placement machine, widely used and highly efficient in the electronics manufacturing industry, suitable for small and medium-sized enterprises or production lines with smaller production scales