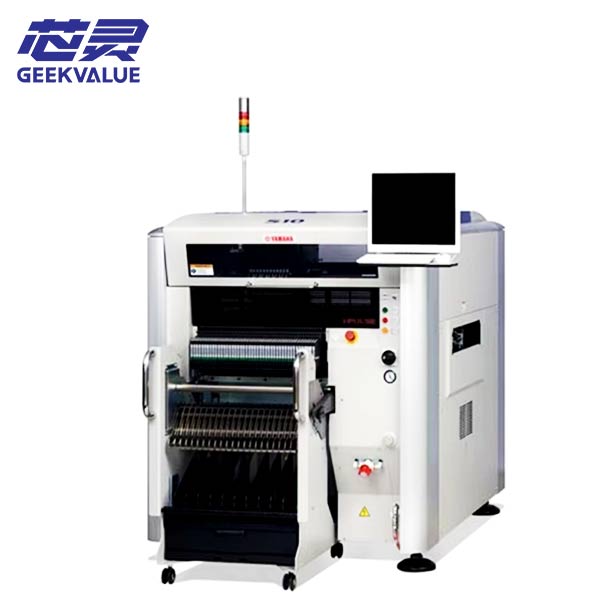

The main functions of the Yamaha SMT machine S10 include efficient and accurate placement operations, high-speed and high-precision placement, support for a variety of production processes, and application scenarios suitable for a variety of industries.

Efficient and accurate placement operations

The Yamaha S10 is a high-performance fully automatic surface mount machine (SMT machine) suitable for the production needs of electronic products of all sizes. Its main function is to accurately place electronic components on the surface of the circuit board. It is suitable for the assembly of various circuit boards. Whether it is a small or large production line environment, it can adapt to circuit boards of different sizes for efficient and accurate component assembly work.

High-speed and high-precision placement

The core advantage of this equipment lies in its ability to combine excellent positioning accuracy with fast installation speed. The placement speed of the Yamaha S10 can reach 45,000 cph (45,000 components per hour) with a resolution of 0.025 mm, ensuring that production efficiency is greatly improved while ensuring product quality.

Support for multiple production processes

In addition to basic component placement, the Yamaha S10 can also support multifunctional process configurations, such as auxiliary operations such as glue spraying and paste coating, to meet the customization needs of different products for special processes. In addition, it also has flexible component/variety corresponding capabilities and highly versatile production interchangeability. The new material change trolley that can be installed with 45 feeder tracks can be mixed with the existing material change trolley.

Application scenarios for various industries

The Yamaha S10 is widely used in automotive electronics, consumer electronics and other fields. Thanks to its flexibility, high reliability and excellent compatibility, it can quickly respond to diverse market needs. In addition, it is easy to maintain and simple to operate, which brings great convenience to the production and operation of enterprises.

3D hybrid module function

The Yamaha S10 also has a 3D hybrid placement function. By adopting a newly developed dispensing head that can be interchanged with the placement head, 3D placement that interacts with solder paste dispensing and component placement becomes possible. In addition, it can be expanded to 3D MID mounting, which can perform solder paste dispensing and component mounting on three-dimensional objects with different heights, angles and directions such as concave and convex surfaces, inclined surfaces, and curved surfaces. It is suitable for automotive/medical equipment, communication equipment, etc. that were difficult to handle in the past.