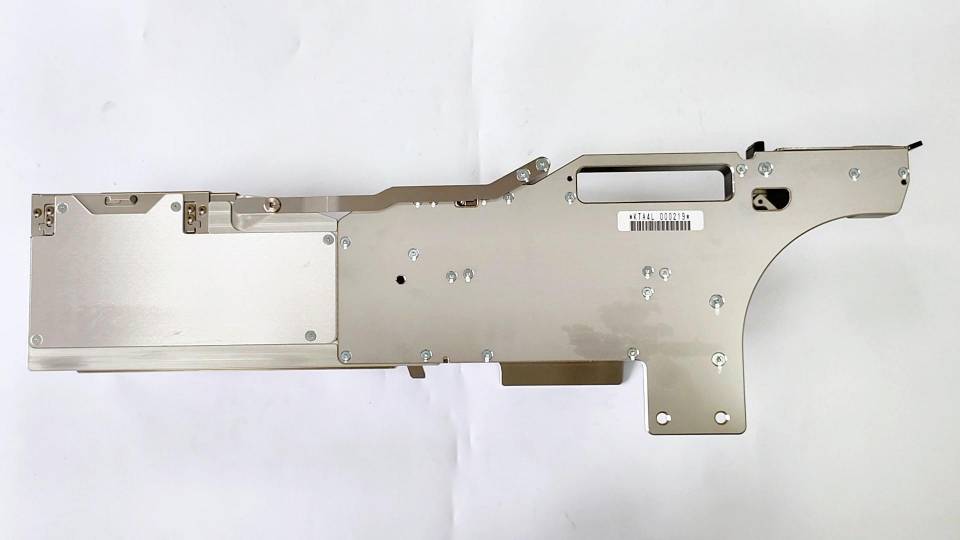

Fuji NXT M3 SMT is a high-performance SMT machine, suitable for the placement of a variety of electronic components.

Performance parameters

The performance parameters of Fuji NXT M3 SMT are as follows: PCB size: minimum 48mmx48mm, maximum 510mmx534mm (double track) SMT speed: H12HS is 22,500 cph, H08 is 10,500 cph, H04 is 6,500 cph, H01 is 4,200 cph

Patch accuracy: H12S/H08/H04 is 0.05mm (3sigma), cpk≥1.00

Patch range: H12S is 0402~7.5x7.5mm, high MAX: 3.0mm; H08 is 0402~12x12mm, high MAX: 6.5mm; H04 is 1608~38x38mm, high MAX: 13mm; H01/H02/OF is 1608~74x74mm (32X180mm), high MAX: 25.4mm

Scope of application and compatibility

Fuji NXT generation M3 patch machine is suitable for the placement needs of various electronic components, with a wide range of patch range and stable performance. Its patch accuracy is high and can meet the placement needs of high-precision electronic components. In addition, the device has good compatibility and can be used with a variety of feeders and tray units to achieve flexible and changeable placement needs.

Other functions

The Fuji NXT first generation M3 placement machine also has the following functions:

Automatic creation of component data: Automatically create component data by acquiring component images, reducing the workload and shortening the operation time.

Data verification function: Ensure the high degree of completion of the created component data and reduce the adjustment time on the machine.

Offline creation of component data: Provide a camera platform with the same camera environment as the machine, and component data can be created offline without using the machine.

In summary, the Fuji NXT first generation M3 placement machine has become an efficient choice in the field of electronic manufacturing with its high performance, high precision and wide range of applications.