Fuji NXT III M6 is a high-performance placement machine, especially suitable for high-speed production lines, with the following main features and advantages:

High speed: In production priority mode, the placement speed of M6 is as high as 42,000 cph (pieces/hour), which can meet the needs of high-speed production lines.

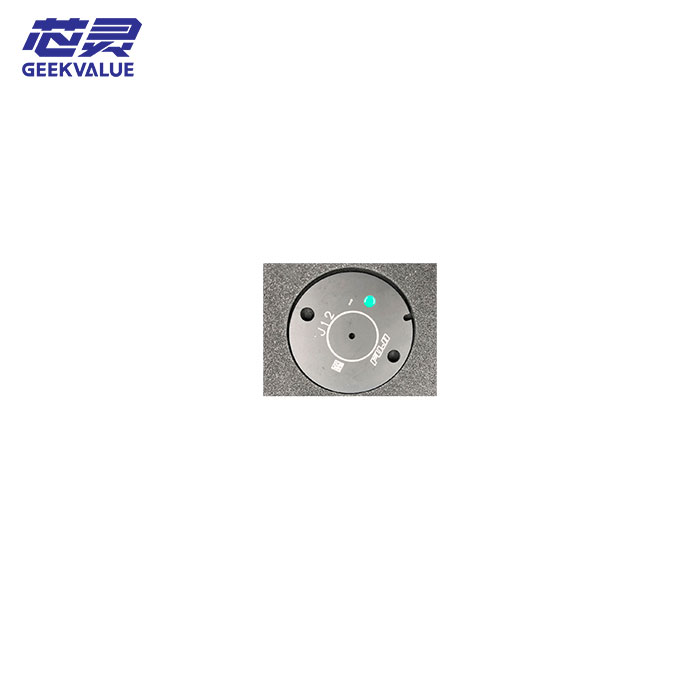

High precision: M6 adopts Fuji's unique high-precision recognition technology and servo control technology, which can achieve a placement accuracy of ±0.025mm to meet the placement needs of high-precision electronic components.

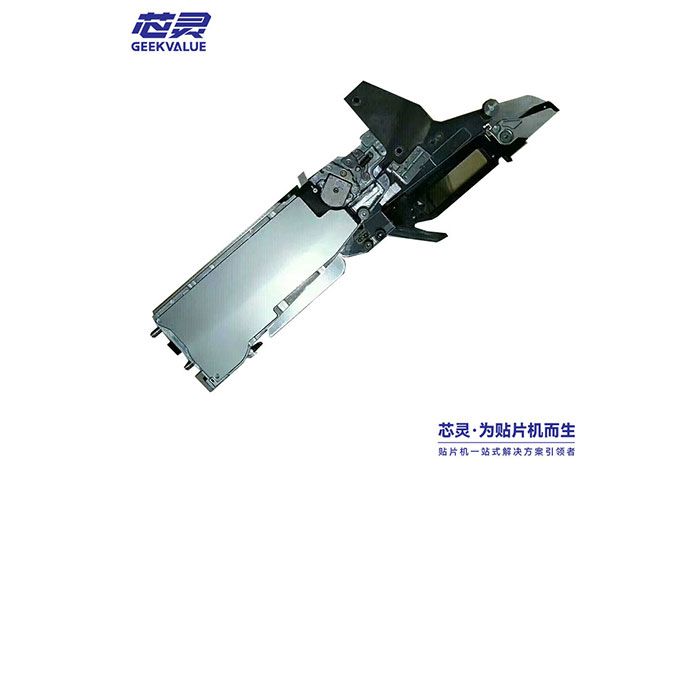

High flexibility: M6 has good compatibility and can be used with a variety of feeders and tray units to achieve flexible and changeable placement needs.

Other functions: M6 also has functions such as automatic creation of component data and reduction of program creation operations when starting production, which further improves production efficiency and flexibility.

Applicable scenarios and cost considerations

M6 is suitable for large enterprises or high-speed production lines, and its efficient production capacity can bring higher economic benefits to enterprises. For production environments that require high speed and high precision, M6 is an ideal choice.

Maintenance and Care

Fuji NXT series SMT machines are easy to maintain. For example, the maintenance of NXT M6 is relatively simple and the maintenance cost is low. In addition, Fuji SMT machines enjoy a good reputation in the market, and their stability and durability are also widely recognized.