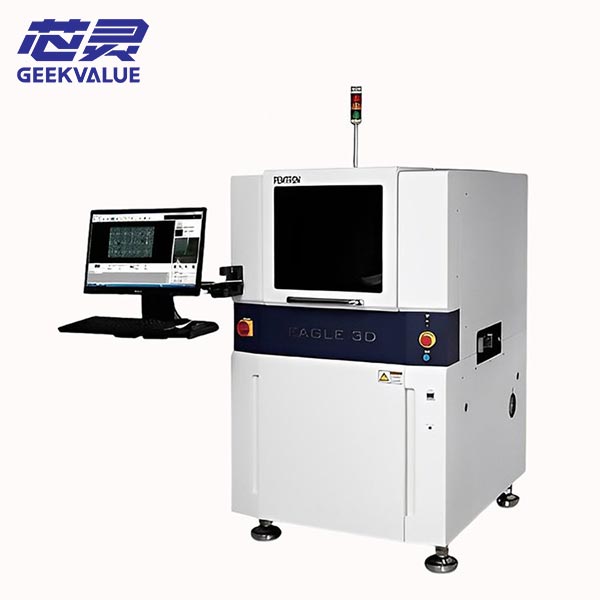

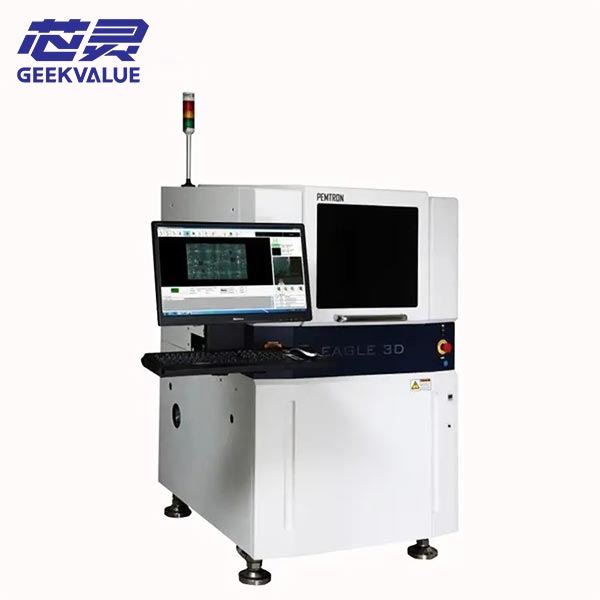

Bentron AOI 8800 is an advanced 3D automatic optical inspection equipment with multiple technical features and functions, suitable for a variety of inspection needs.

Technical Features High-speed inspection and measurement technology: Bentron AOI 8800 adopts advanced high-speed inspection and measurement technology, capable of shadow-free high-speed inspection and measurement, ensuring 100% 2D and 3D full inspection, guaranteeing completely shadow-free optical inspection and low false alarm rate, while maintaining high flexibility. High-precision inspection: The equipment uses 8 projected lights + 3 layers of 2D light sources, combined with 2D and 3D synchronous inspection algorithms, telecentric lenses provide high-precision inspection, and high-configuration CPU and GPU guarantee image processing. 3D inspection technology: Supports all-round 3D inspection, capable of measuring solder height and volume, and improving the detection ability of defective products. User-friendly interface: The equipment has a simple and clear user interface, a standard component library management system and an offline real-time debugging system (option), making operation and maintenance more convenient. Application scenarios

Bentron AOI 8800 is suitable for a variety of scenarios, including:

PCB inspection: It can perform 100% 2D and 3D inspection on PCBs, ensuring shadow-free optical inspection and low false alarm rate.

Component inspection: It can detect components of various geometric shapes and provide high-precision inspection results.

Plug-in pin inspection: It is suitable for the inspection of plug-in pins with special algorithm support.

Performance parameters

The main performance parameters of Bentron AOI 8800 include:

Camera resolution: 9 million pixels with a resolution of 10um.

Inspection speed: Up to 44.55cm²/Sec.

Field of view (FOV): Up to 54×54mm.

Maximum PCB size: 510×600mm.

Power requirements: 220~240 VAC, 1 Phase, 50/60Hz.

User evaluation and market positioning

Bentron AOI 8800 has a high evaluation in the market, and users report that it has stable performance, high detection accuracy, and easy operation. Its high speed and high precision make it perform well in SMT production lines and suitable for industrial environments that require efficient and high-precision detection.

In summary, Bentron AOI 8800 is an advanced 3D automatic optical inspection equipment that integrates high speed, high precision, and user-friendliness. It is suitable for a variety of industrial scenarios and can meet users' needs for high-quality detection.