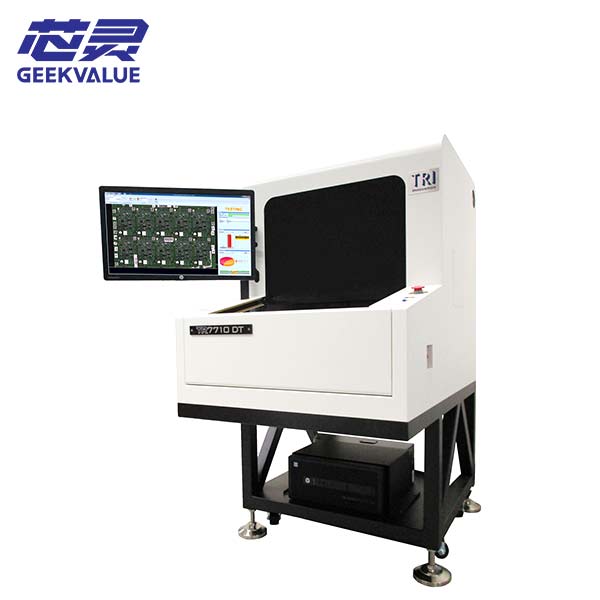

TR7710 is an economical, high-performance online automatic optical inspection (AOI) equipment designed for high-precision component inspection.

Main functions and technical features High-resolution camera system: TR7710 is equipped with a high-sensitivity 6.5-megapixel high-speed color camera that can capture fine PCB board images. Multi-phase light source: Using TRI's unique multi-phase light source, it provides a variety of gap height options and improves the depth of field range, which is suitable for high component inspection. Defect detection: Combined with excellent defect detection functions, it can accurately identify various defects such as short circuits, displacements, missing parts, etc. Intelligent programming design: It has a simple and intelligent CAD programming design, which reduces programming time and is suitable for NPI (new product introduction) optimization. High depth of field range: It provides a high depth of field range to ensure that components with higher heights can also obtain clear inspection images. Multi-phase light source: It uses four-way adjustable variable digital stripe light projection to provide superior 3D inspection capabilities. High-speed detection: At 10µm optical resolution, the imaging speed is 27 cm²/second; at 12.5µm optical resolution, the imaging speed is 43 cm²/second.

Application scenarios and user reviews

TR7710 is widely used in quality control of SMT (surface mount technology) production lines, which can significantly improve production efficiency and product yield. Its simple programming interface and efficient defect detection function enable operators to quickly get started, reduce misjudgments, and improve the stability and reliability of the overall production line. In addition, TR7710 also supports customized needs of various budgets and has high cost-effectiveness