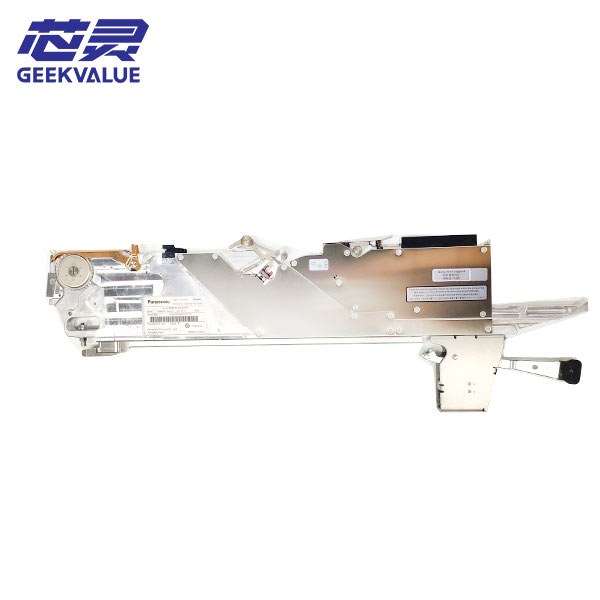

Panasonic SMT tray je zariadenie pre SMT (technológiu povrchovej montáže) vyrábané spoločnosťou Panasonic, používané hlavne na automatické umiestňovanie komponentov v procese výroby elektroniky. Panasonic SMT zásobník má nasledujúce vlastnosti a funkcie:

Technické indikátory: Panasonic SMT zásobník má funkciu programovania súradníc, prijíma riadenie servosystému a dokáže dosiahnuť presné vizuálne polohovanie XYZ s tromi súradnicami. Umiestňovacia hlava je riadená programom PLC+dotyková obrazovka, podporuje automatické podávanie podávača, vhodné pre montáž komponentov 01005, s presnosťou ±0,02MM, CPK≥2 a teoretickou kapacitou 84000 Pich/H.

Hlavné funkcie: Podnos SMT Panasonic sa používa hlavne na umiestnenie komponentov SMT a môže dokončiť automatické umiestnenie komponentov, čím spĺňa požiadavky na montáž komponentov 01005.

Spôsob prevádzky: Spôsob prevádzky zásobníka Panasonic SMT zahŕňa odoslanie programu s zásobníkom, kontrolu počiatočnej polohy odsávania a databázy zásobníka atď. Ak sa na nahranom stroji vyskytne abnormalita, je potrebné skontrolovať, či sa spustenie odsávania poloha zásobníka a databázy sú abnormálne. V prípade potreby je možné štandardnú databázu nahradiť.

Rozsah použitia: Zásobník umiestňovacieho stroja Panasonic je široko používaný v oblasti elektronickej výroby, vhodný na výrobu rôznych elektronických produktov a zlepšuje efektivitu výroby a presnosť umiestnenia.

Údržba a riešenie problémov: Ak počas používania narazíte na zlyhanie pri nahrávaní programu, môžete skontrolovať, či počiatočná poloha nasávania a databáza nie sú abnormálne. Ak problém stále pretrváva, môžete skúsiť nahradiť štandardnú databázu.

Stručne povedané, zásobník umiestňovacieho stroja Panasonic hrá dôležitú úlohu v oblasti výroby elektroniky s vysokou presnosťou, vysokou účinnosťou a automatizovanou prevádzkou.