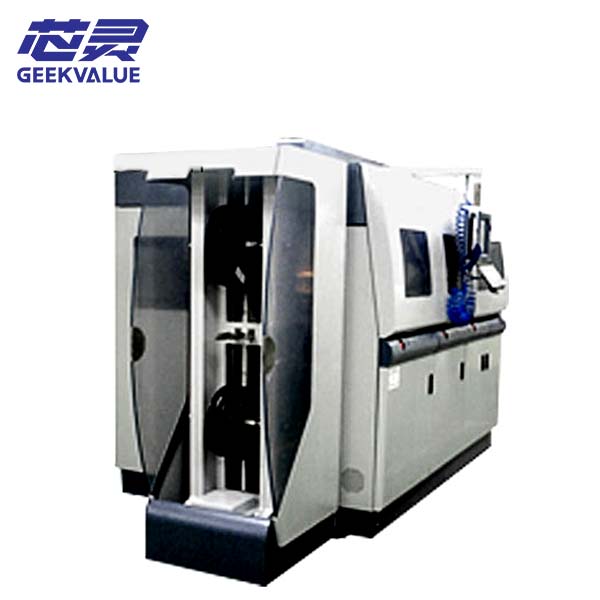

The fully automatic wire bonding machine AB383 is a high-tech semiconductor manufacturing equipment, mainly used to realize the key step in the microelectronics process - wire bonding. Its equipment structure includes power supply, motion system, optical system, control system and auxiliary system. The power supply provides energy, the motion system drives the X, Y, and Z axes of the wire bonding machine to move precisely, the optical system provides light source, the control system operates as a whole through the central processor, and the auxiliary system includes cooling, pneumatic and sensor systems, etc., to provide necessary support and guarantee for the equipment.

Working principle

The working principle of the AB383 wire bonding machine mainly includes the following steps:

Positioning: Move the wire bonding head to the specified position through the motion system.

Optical positioning: Position the two objects to be welded through the optical system.

Precise control: The control system performs precise control to align the wire bonding head with the two objects to be welded.

Welding: Provide energy through the power supply to connect the wire bonding wire to the two objects.

Advantages and application scenarios

The advantages of the AB383 wire bonding machine are its accuracy, stability and high efficiency. Its precise positioning and welding technology can ensure accurate welding of tiny objects, and its efficient workflow can improve production efficiency. Its main application scenarios include integrated circuit manufacturing, solar cell manufacturing, LED manufacturing and other fields that require micron-level precision welding.