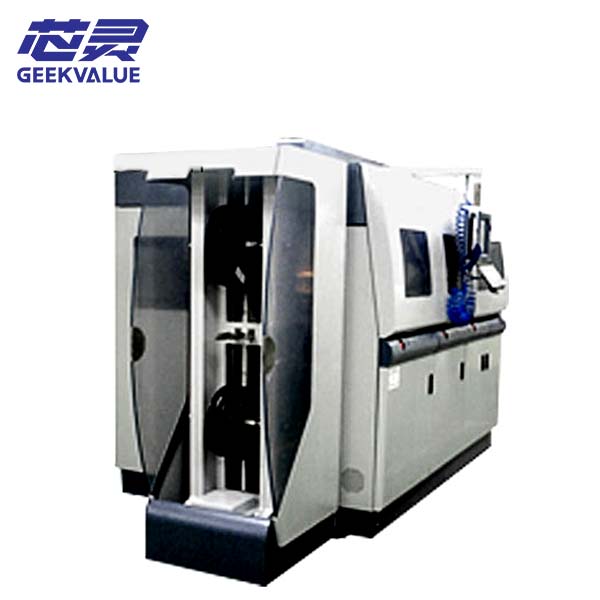

ASMPT laminator IDEALmold™ 3G is an advanced automatic molding system, especially suitable for processing strip and roll substrates. The system has the following main features and functions:

Processing range: IDEALmold™ 3G can process lead frame substrates with a maximum size of 100mm x 300mm.

Scalability: The system supports operations from 1 press to 4 presses, suitable for production needs of different scales.

Parameterization setting: Supports parameterization of 2-8 molds, providing flexible mold configuration options.

Pressure selection: Provides 120T and 170T pressure options to meet the laminating needs of different materials.

Connection function: FOL row group and PEP row group connection function are available for easy integration with other equipment.

SECS GEM function: Supports SECS GEM function for easy integration with automated production lines.

Packaging options: Including ASMPT's patented PGS Top Gate packaging option, providing a variety of packaging solutions.

Cooling solution: Double-sided cooling (DSC) mold solution is available to ensure temperature control during the plastic sealing process.

Vacuum performance: SmartVac 2-tray vacuum pressure performance is used to ensure stability during the plastic sealing process.

Expansion module: Supports a variety of expansion modules, such as Top & Bottom FAM, Line Scan Post Mold Inspection, Motorized Wedge, Precision Degate, SmartVac, etc.