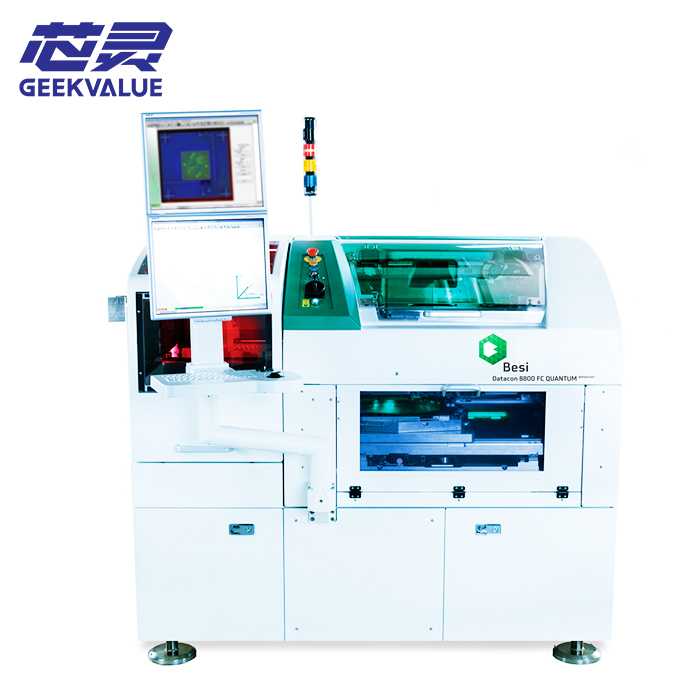

High-Precision, High-Efficiency Die Bonding Solution

The BESI Datacon 8800 is a high-performance die bonding machine specifically designed for semiconductor packaging, LED packaging, and precision electronics manufacturing. With its advanced technology, the Datacon 8800 delivers fast and precise die attach processes for various chip and substrate types, making it ideal for use in electronics production.

Die Bonding Machine Key Features:

High-Precision Vision Alignment System: Automatic calibration ensures every die bonding process is accurate and error-free.

Modular Design: Flexible configuration options, allowing for customization based on production needs.

Efficient Production Capability: Fast and stable operation, suitable for high-volume production.

Automated Process Control: Smart control systems reduce human intervention and improve production stability.

Applications:

The Datacon 8800 is widely used in semiconductor packaging, LED packaging, and electronic component manufacturing, particularly in environments that require high-precision die bonding.

Die Bonding Machine Suitable for:

Small and Large Chip Packaging: Whether dealing with small chips or large substrates, the Datacon 8800 provides reliable die bonding solutions.

Various Electronic Components: Ideal for precise bonding of electronic components such as power modules, LEDs, sensors, and more.

The Datacon 8800, with its high efficiency, precision, and flexibility, is an essential part of modern electronic assembly production lines, helping customers enhance production efficiency and ensure product quality.

Besi Datacon 8800 is an advanced chip bonding machine, mainly used for 2.5D and 3D packaging technology, especially TSV (Through Silicon Via) applications.

Technical features and application areas

Besi Datacon 8800 chip bonding machine adopts thermocompression bonding technology, which is a key technology in the current 2.5D/3D packaging technology. Its core advantages include:

Thermocompression bonding technology: suitable for 2.5D and 3D packaging, especially TSV applications.

7-axis key head: a key head with 7 axes, providing higher precision and flexibility.

Production stability: has excellent production stability and high productivity.

Performance parameters and operating platform

Besi Datacon 8800 chip bonding machine has the following performance parameters and operating platform:

7-axis key head: contains 3 positioning axes (X, Y, Theta) and 4 bonding axes (Z, W), providing precise positioning and bonding control.

Advanced Hardware Architecture: Unique 7-axis key head and advanced hardware architecture ensure ultra-fine pitch capability.

Control Platform: A new generation control platform with higher motion control and lower latency, enhanced trajectory control and process variable tracking capabilities.

Industry Application and Market Positioning

Besi Datacon 8800 chip bonding machine has a wide range of applications in 2.5D and 3D packaging, especially in the research and development of high-bandwidth memory (HBM) and AI chips, hybrid bonding technology has become an important means to achieve the next generation of HBM (such as HBM4). Due to its high precision and high stability, the equipment performs well in TSV applications and has become a reference tool for current TSV applications.