Detailed introduction:

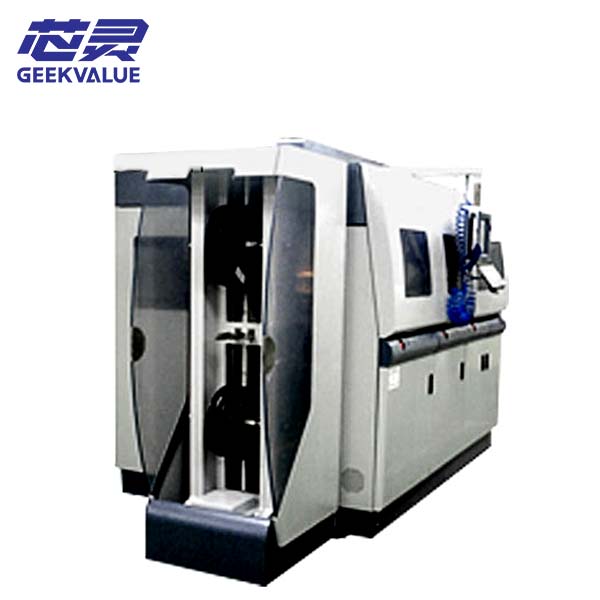

ASMPT Pacific Panel Welding Solution - AD420XL

- High speed

102ms die bonding cycle*@6mm pitch

- High precision

±μm@∂*±1°@3∂*

- High flexibility

Suitable for both backlight applications and small pitch RGB LED direct display screens

Large substrate processing capacity, 500mmx600mm*

- High density

Dense to 20μm chip gap*

Small pitch as small as P0.4RGB LED direct display screen

Specifications

Pacific Panel Welding Solution-AD420XL is a die bonder designed for Mini LED, suitable for backlight applications and small-pitch RGB LED direct display screens. Its main parameters and features are as follows:

Die bond cycle: 102ms (6mm pitch).

Accuracy: High precision, error range within ±1μm.

Flexibility: Suitable for backlight applications and small-pitch RGB LED direct display screens, with a large substrate processing capacity of 500mmx600mm.

Chip gap: Can handle small-pitch P0.4RGB LED direct display screens with chip gaps as dense as 20μm.

Patch speed: 120ms (1.5mm pitch), 130ms (6mm pitch).

Power supply requirement: 240V.

Weight: 950kg.

These parameters make AD420XL excel in high speed, high precision and high flexibility, and are particularly suitable for Mini LED application scenarios.