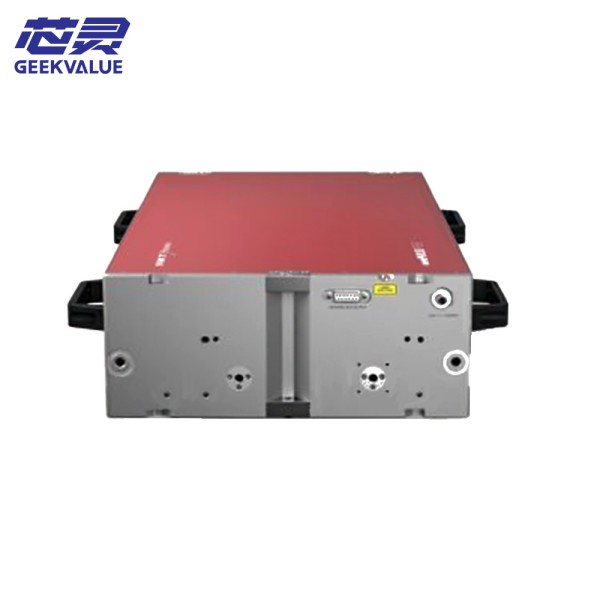

DISCO Corporation is a global leader in precision machining. Its aeroPULSE FS50 is an ultraviolet (UV) nanosecond pulse laser designed for high-precision micromachining. It is widely used in precision cutting, drilling and surface treatment in the semiconductor, electronics, medical device and other industries.

1. Core functions and features

(1) High-precision UV laser processing

Wavelength: 355nm (UV), with a very small heat-affected zone (HAZ), suitable for brittle material processing.

Short pulse (nanosecond level): Reduces material thermal damage and improves edge quality.

High repetition rate (up to 500kHz): Takes into account both processing speed and precision.

(2) Intelligent beam control

Beam quality (M²≤1.3): Small focused spot (up to 10μm level), suitable for Micron-level processing.

Adjustable spot mode: Supports Gaussian spot or flat-top spot to meet the needs of different materials.

(3) High stability and long life

Solid-state laser design, maintenance-free, life> 20,000 hours.

Мониторинг энергопотребления в режиме реального времени для обеспечения согласованности обработки.

(4) Automation compatibility

Supports EtherCAT and RS232 communication protocols and can be integrated into automated production lines or robotic arm systems.

2. Key Specifications

Parameters aeroPULSE FS50 Specifications

Laser type UV nanosecond pulse laser (DPSS)

Wavelength 355nm (UV)

Average power 10W (higher power optional)

Single pulse energy 20μJ~1mJ (adjustable)

Pulse width 10ns~50ns (adjustable)

Repetition rate 1kHz~500kHz

Beam quality (M²) ≤1.3

Spot diameter 10μm~100μm (adjustable)

Cooling method Air cooling/water cooling (optional)

Communication interface EtherCAT, RS232

3. Typical application areas

(1) Semiconductor industry

Wafer cutting (brittle materials such as silicon, silicon carbide, GaN, etc.).

Chip packaging (RDL wiring, TSV drilling).

(2) Electronic manufacturing

PCB micro-hole drilling (HDI board, flexible circuit).

Glass/ceramic cutting (mobile phone cover, camera module).

(3) Medical devices

Stent cutting (cardiovascular stents, precision metal parts).

Biosensor processing (microfluidic chips).

(4) Research fields

Micro-nanostructure preparation (photonic crystals, MEMS devices).

4. Comparison of technical advantages

Features aeroPULSE FS50 Ordinary UV laser

Pulse control Nanosecond level, adjustable pulse width Fixed pulse width

Heat affected zone Extremely small (HAZ<5μm) Large (HAZ>10μm)

Automation integration Support EtherCAT Basic RS232 only

Applicable materials Brittle materials (glass, ceramics) General metals/plastics

5. Применимые отрасли

Semiconductor packaging and testing

Consumer electronics (5G devices, display panels)

Medical devices (implants, diagnostic equipment)

Precision optics (filters, diffraction elements)

6. Резюме

DISCO aeroPULSE FS50 core value:

Ultraviolet nanosecond laser - ideal for precision processing of brittle materials.

High beam quality (M²≤1.3) - achieve micron-level processing accuracy.

Intelligent control and automation compatible - adapt to Industry 4.0 production lines.

Long life and maintenance-free - reduce comprehensive use costs.

This equipment is particularly suitable for scenarios with strict requirements on processing accuracy and edge quality