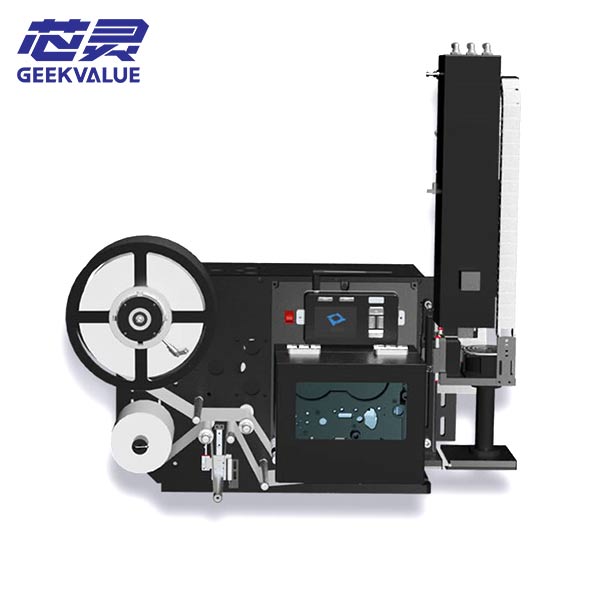

O alimentador de impressão e etiquetagem on-line é um equipamento automatizado que integra alimentação, impressão e etiquetagem. É amplamente utilizado na produção de materiais eletrônicos e fábricas SMT, e é usado principalmente para impressão de etiquetas e etiquetagem de bandejas de materiais eletrônicos. Suas principais funções incluem alimentação automática, impressão e etiquetagem, e verificação do conteúdo da etiqueta, o que pode melhorar significativamente a eficiência da produção e a precisão da etiquetagem.

Principais funções e parâmetros técnicos

Alimentação automática: O equipamento é equipado com um rack de carregamento de bandejas com várias estações, que podem carregar e corrigir automaticamente a posição da bandeja para garantir que cada bandeja de material possa entrar no fluxo de trabalho com precisão. Impressão e etiquetagem: O equipamento é conectado ao sistema MES e chama automaticamente o modelo de impressão correspondente de acordo com as informações da etiqueta para concluir a impressão e etiquetagem da etiqueta. A precisão da etiquetagem é alta e o erro está dentro de mais ou menos 1 mm. Verifique o conteúdo da etiqueta: Por meio da função de reinspeção CCD, a precisão do conteúdo da etiqueta é garantida, o erro é reduzido e a qualidade do produto é melhorada. Cenários aplicáveis e aplicações industriais

O alimentador de impressão e etiquetagem on-line é adequado para fabricantes de materiais eletrônicos e fábricas de SMT, usado principalmente para etiquetagem de produtos acabados e etiquetagem de materiais recebidos. Sua alta eficiência e precisão podem simplificar muito o processo de operação, reduzir a intervenção manual e melhorar a eficiência geral da produção. Em resumo, o alimentador de impressão e etiquetagem on-line melhorou significativamente a eficiência de impressão e etiquetagem de etiquetas da produção de materiais eletrônicos e fábricas de SMT por meio de design automatizado e inteligente, reduziu as operações manuais e reduziu a taxa de erro. É um alimentador multifuncional indispensável na produção industrial moderna.