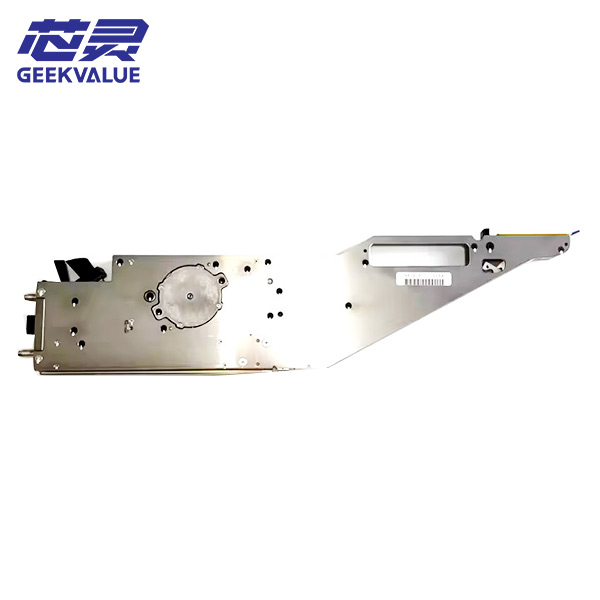

Fuji SMT børstemater er en nøkkelkomponent som brukes til å transportere komponenter i SMT patch-behandling, vanligvis kalt en mater eller mater. Hovedfunksjonen er å nøyaktig transportere komponenter fra materialbeltet til arbeidshodeposisjonen til SMT-maskinen for å sikre nøyaktigheten og effektiviteten til lappen.

Typer og spesifikasjoner

Det finnes mange typer Fuji SMT-matere, hovedsakelig inkludert følgende:

Etter matemetode: skivemater, beltemater, bulkmater, tubemater.

Med elektrisk og ikke-elektrisk: elektrisk mater og mekanisk mater.

Etter gjeldende utvalg: generell mater og spesialformet mater.

Etter SMT-maskintype: høyhastighets SMT-mater, generell SMT-mater, elektrisk pneumatisk mater.

Spesifikke modeller og anvendelig omfang

De spesifikke modellene av Fuji SMT-matere inkluderer NXT-serien, CP-serien, IP-serien, XP-serien, GL-serien og QP-serien, etc. For eksempel er NXT-seriens mater egnet for NXT-serien SMT-maskin, og NXT-serien SMT-maskin materen kan deles inn i 4 mm, 8 mm, 12 mm, 16 mm, 24 mm og 32 mm i henhold til bredden på materialstrimmelen for å møte ulike produksjonsbehov. Vedlikehold og stell For å sikre normal drift og forlenge levetiden til Fuji SMT børstemateren, anbefales det å utføre følgende vedlikehold og stell regelmessig: Rengjøring: Rengjør regelmessig støv og urenheter i og utenfor materen for å sikre jevn. overføring av komponenter. Inspeksjon: Kontroller slitasjen på girmekanismen og plukkemekanismen, og skift ut skadede deler i tide. Smøring: Smør transmisjonsdelene riktig for å redusere friksjon og slitasje. Kalibrering: Kalibrer posisjonen og hastigheten til materen regelmessig for å sikre nøyaktigheten til komponentleveransen