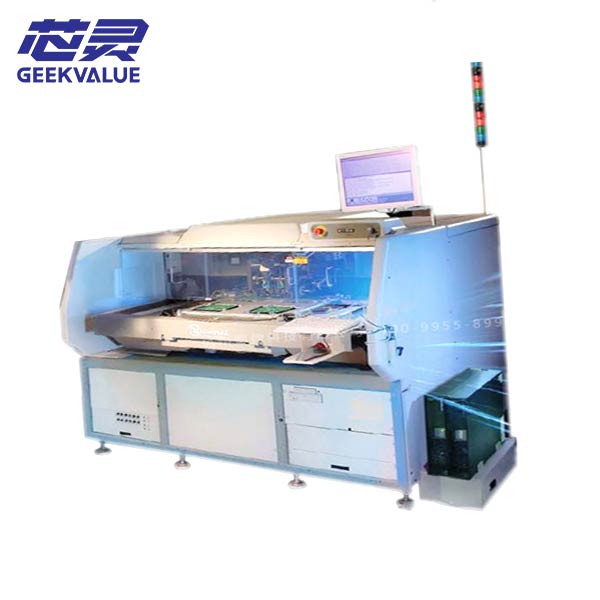

Global Plug-in Machine 6241F er en helautomatisk horisontal plug-in maskin, hovedsakelig brukt til plug-in av elektroniske deler med delkroppen flatt mot PCB-kortet.

Hovedfunksjoner og aktuelle objekter

Hovedfunksjonene til Global Plug-in Machine 6241F inkluderer:

Helautomatisk plugg inn av elektroniske deler med delkroppen flatt mot PCB-kortet: egnet for teipede dioder, motstander, fargeringinduktorserier, lys (jumpere) eller andre elektroniske deler med teipet flatt mot PCB.

Plug-in span justering: minimum 5 mm, maksimum 22 mm, egnet for elektroniske komponenter av forskjellige størrelser.

Hastighet: 28 000 deler kan behandles i timen.

Gjeldende scenarier og ytelsesparametere

Gjeldende scenarier: Egnet for automatisert plug-in-produksjon av elektroniske komponenter, egnet for ulike produksjonsmiljøer som krever effektiv og presis plug-in.

Ytelsesparametere:

Effekt: 1,5KW/time

Dimensjoner: 4,2 M lang, 1,8 M bred, 1,8 M høy (60 stasjoner) Vekt: 2000 kg Strømforbruk: 1,5 KW/time Vedlikeholds- og vedlikeholdsmetoder Vedlikehold og vedlikehold av Global Plug-in Machine 6241F inkluderer hovedsakelig følgende aspekter: Regelmessig sjekk og rengjør innsiden og utsiden av maskinen for å sikre jevn drift av maskinen. Skift regelmessig ut slitte deler som kuttere, transportbånd osv. Kalibrer regelmessig spennvidden og høyden på plug-in-hodet for å sikre plug-in-nøyaktighet. Hold maskinen smurt for å redusere friksjon og slitasje. Gjennom ovennevnte vedlikeholds- og vedlikeholdstiltak kan maskinens levetid forlenges og produksjonseffektiviteten forbedres.