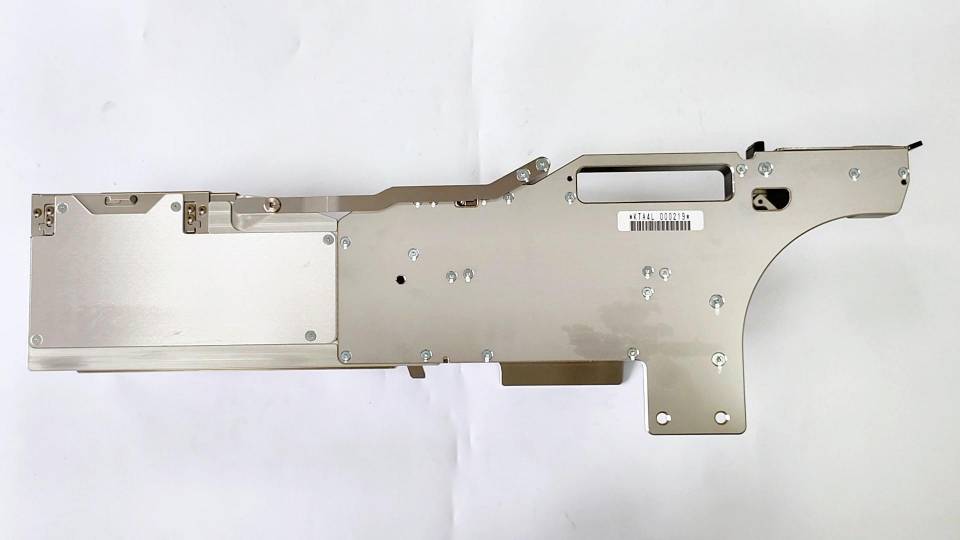

Fuji SMT 16mm-invoeris een belangrijk onderdeel van de SMT-machine, die voornamelijk wordt gebruikt om componenten uit de lade te halen en ze nauwkeurig op het PCB-bord te plaatsen. De functies omvatten voornamelijk de volgende aspecten:

Componentlevering en positionering:De 16mm feeder zorgt ervoor dat de schuif door de motor beweegt, klemt of absorbeert de componenten met een bepaalde snelheid en plaatst ze vervolgens op de printplaat volgens de vooraf ingestelde positie om de nauwkeurige plaatsing van de componenten te garanderen.

Verbeter de productie-efficiëntie en nauwkeurigheid: De kalibratie van de feeder kan ervoor zorgen dat de componenten worden opgepakt en op de juiste positie worden geplaatst, waardoor de downtime en foutfrequentie van de SMT-machine worden verminderd en de productie-efficiëntie wordt verbeterd. Nauwkeurige kalibratie kan ook de nauwkeurigheid van de patch garanderen, onnauwkeurige plaatsing door positie-offset voorkomen en de productkwaliteit beïnvloeden.

Geschikt voor verschillende componenttypen:De feeder is geschikt voor een groot aantal componenten, waaronder chips van formaat 0201, QFP (quad flat package), BGA (ball grid array package) en Connector (connector), enz. De flexibele robotarm en het nauwkeurige besturingssysteem kunnen gemakkelijk voldoen aan de behoeften van componentplaatsing van verschillende groottes en vormen.

Onderhoud en verzorging: Om de normale werking van de voederbak te behouden, is regelmatig onderhoud vereist. Dit omvat het schoonmaken van de voederbak om stofophoping te voorkomen, regelmatig oliën om wrijving te verminderen, het vervangen van het luchtfilter en het controleren van onderdelen.

Kalibratiemethode: Feederkalibratie vereist professionele technologie en precisie-instrumenten. Veelvoorkomende kalibratiemethoden zijn visuele systeemkalibratie, mechanische kalibratie en softwarekalibratie. Visuele systeemkalibratie voert referentiepuntkalibratie uit door de camerapositie en brandpuntsafstand aan te passen; mechanische kalibratie wordt aangepast door de positie en hoek van de feeder te meten; softwarekalibratie wordt automatisch gekalibreerd via de bijpassende kalibratiesoftware.

Dankzij de bovenstaande functies en onderhoudsmaatregelen speelt de 16mm feeder een cruciale rol bij de SMT-patchverwerking. Hij zorgt voor een stabiele werking en efficiënte productie van de patchmachine.