Xiton Laser IXION 193 SLM is a single-frequency all-solid-state laser system with unique and important applications in scientific research and industry. Its core technology revolves around generating laser output with specific wavelength and high stability, providing solutions for many scenarios with strict requirements on laser parameters.

(II) Features

Precise wavelength output: The central wavelength can be customized in the range of 185-194 nm, and can be configured as a fixed wavelength after the order is confirmed, with an accuracy of up to 0.01 nm. The commonly used operating wavelength is 193.368 nm, and this deep ultraviolet wavelength plays an irreplaceable role in many applications.

Stable pulse characteristics: The output pulse energy is 1.6 μJ, the pulse duration is 8 ns-12 ns, and the repetition frequency range is 1 kHz-15 kHz. In addition, the high inter-pulse stability, σ<2.5%, ensures the consistency of laser output during repeated work, which is critical for experiments or processing tasks that require precise energy control.

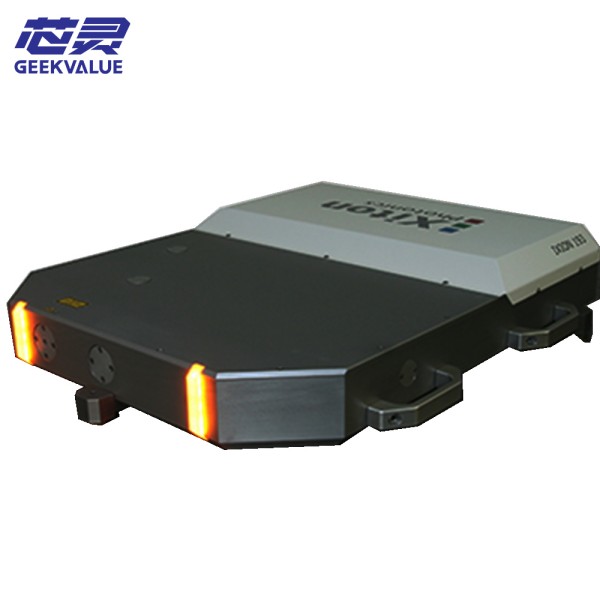

Compact structural design: The laser head measures 795 mm x 710 mm x 154 mm and weighs 74 kg; the power supply and cooling device measures 600 mm x 600 mm x 600 mm and weighs 78 kg. The overall compact design ensures high performance while reducing space occupancy and is easy to integrate into different working environments. Its working power requirement is AC 85 V - 264 V, and the power consumption is 650 W, which meets the CDRH safety standards.

2. ಸಾಮಾನ್ಯ ದೋಷ ಮಾಹಿತಿ

(I) Power-related faults

Main power fault alarm: When the input main power voltage exceeds the ±10% range or the input phase sequence is wrong, the main power fault alarm will be triggered. At this time, the main power supply, computer and high-voltage power supply will be turned off, the laser system will not work properly, and the display may not show any text. This may be caused by grid voltage fluctuations, loose or damaged power cord connections, internal faults in the power module, etc.

(II) Abnormal laser output failure

Reduced output power: Possible reasons include decreased performance of the laser gain medium, reduced pump source power, and increased laser transmission loss due to contamination or damage of optical components. For example, dust, oil and other pollutants on the surface of the optical lens in the laser cavity will cause the laser to scatter and absorb during reflection and transmission, thereby reducing the output power.

(III) Cooling system failure

Alarm for excessive cooling water temperature: The cooling system is responsible for removing the heat generated during the operation of the laser system to ensure that key components such as the laser gain medium and pump source operate within a suitable temperature range. If the cooling water temperature is too high and exceeds the set threshold (usually 25-30°C, the specific temperature depends on the equipment requirements), an alarm will be triggered. The reasons for this situation may be insufficient cooling water, cooling water pump failure, poor heat dissipation of the cooler (such as dust accumulation on the radiator, fan failure), etc.

III. ನಿರ್ವಹಣಾ ವಿಧಾನಗಳು

(I) Regular maintenance

Optical system maintenance: Perform a comprehensive inspection and maintenance of the optical system regularly (for example, 3-6 months, the specific time depends on the actual use). Use professional optical testing equipment, such as beam quality analyzers and spectrometers, to test parameters such as beam quality and spectral bandwidth. If optical components are found to be contaminated or damaged, they should be cleaned or replaced in time.

(II) Maintenance after fault repair

Compehensive inspection: After the laser system is repaired, do not put it into normal use immediately, but conduct a comprehensive inspection. Recheck the working status of all relevant components to ensure that the fault has been completely eliminated and no other new problems have been caused. For example, after replacing the laser gain medium, remeasure the output power, pulse energy, wavelength and other parameters of the laser, and compare them with the nominal value of the equipment to ensure that the performance has returned to normal.

Record maintenance files: Record the fault phenomenon, repair process, replaced parts and test results after repair in detail, and establish a complete equipment maintenance file. These files not only help track the maintenance history and performance changes of the equipment, but also provide important references for subsequent maintenance and improvements.