Nella fabbrica SMT, quando la macchina di posizionamento ASM tedesca è in funzione, i principali fattori che causano il funzionamento anomalo dei componenti elettrici sono: tensione di ingresso instabile della rete elettrica, spegnimento anomalo, temperatura e umidità ambiente, polvere e altri fattori; la frequente sostituzione a caldo di alimentatori e vassoi ugelli aumenterà anche il tasso di guasto dell'FCU. Pertanto, la temperatura, l'umidità e la polvere nell'officina devono essere monitorate e ottimizzate in tempo reale, il che può ridurre notevolmente il tasso di guasto dell'apparecchiatura. Oggi, vorrei condividere con voi i metodi di gestione e le idee di manutenzione quando il nucleo di controllo X-FCU dell'alimentatore e del cambio ugello della macchina di posizionamento della serie X S è anomalo. Il numero di parte corretto dell'X-FCU (slot40) è: 03096377 (vecchio modello), 03170613 (nuovo modello).

Di seguito sono riportate le idee di manutenzione effettive del vecchio X-FCU:

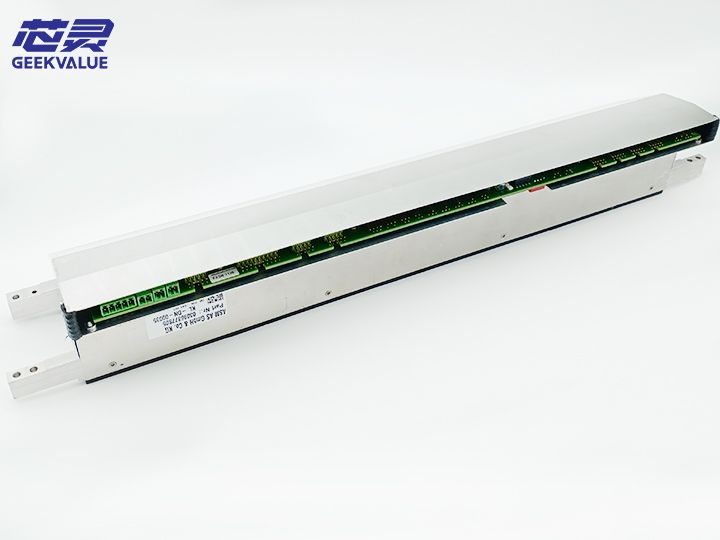

1. X-FCU è il nucleo di controllo dell'alimentatore, della piastra di distribuzione dell'ugello e della taglierina. È composto principalmente dalle seguenti parti funzionali:

1) Controllo dell'alimentatore

2) Controllo del cambio ugello e del contenitore rifiuti

3) Controllo del taglio delle strisce

2. La scheda di controllo interna X-FCU è composta dalle seguenti parti:

Scheda di controllo-FBG_FCU-X: 03092560-03

*1) Descrizione della porta del connettore di controllo

X7: ingresso tensione 26-28V, pin4-+ingresso 26-28V, pin2-GND

X3: segnale di comunicazione canbus, pin2, 5: LGND/pin3: CAN_L/pin4: CAN_H

X4/13: Blocco di sicurezza del carrello

X11: Rilascio dell'alimentatore

X23: Controllo elettrovalvola cilindro per cambio ugello

X21-22: Sensore di rilevamento del contenitore dei rottami

X5-10: Sistema di taglio

X12-13: Porta di comunicazione del cambio ugello

X26: ingresso 24V

Scheda di controllo EDIF - 2 PZ: 03115477-06 - Ogni scheda può controllare 20 alimentatori da 8 mm.

Descrizione della funzione: Queste due schede sono principalmente responsabili del controllo della comunicazione di alimentazione dell'alimentatore

I guasti comuni di X-FCU includono principalmente i seguenti guasti:

Non riesco ad accenderlo

Errore di comunicazione Canbus - Il sottosistema Tabella xx non risponde, impossibile rilevare la versione ISS.

Idee di riparazione:

1) Per l'alimentazione anomala della FCU, controllare uno per uno i terminali di ingresso di alimentazione di X7 e 26. I 24 V sono collegati direttamente all'LM3175 e convertiti in 12 V. Il terminale di uscita dell'LM3175 è utilizzato come terminale di ingresso di alimentazione dell'82F4 e viene convertito in 5 V per fornire alimentazione al circuito integrato di controllo principale; l'uscita dell'LM3175 Il terminale è utilizzato come ingresso di alimentazione del chip di alimentazione 81J9, che viene convertito in 3,3 V per fornire alimentazione al circuito integrato logico. Il metodo di misurazione statica può misurare se 24 V, 5 V, 3,3 V e GND sono in cortocircuito, in modo che sia possibile valutare la maggior parte dei guasti dell'alimentazione.

2) Errore di comunicazione, basta seguire i pin 3 e 4 di X3 per trovare i pin di ricezione 6 e 7 del transceiver canbus TLE6250G, trovare i pin 1 e 4 del chip can consultando il datasheet dell'IC per trovare il driver di controllo principale IC e misurare il segnale di comunicazione in tempo reale tramite l'oscilloscopio. La forma d'onda della tensione può essere utilizzata per determinare il punto di guasto specifico. La manutenzione per la FCU può sostanzialmente risolvere la maggior parte dei guasti qui.

Dopo che tutti i punti di errore sopra indicati sono stati rilevati e la manutenzione è OK, è il momento di testare la macchina. Questa è l'idea di manutenzione di Xinling Industry per il montatore serie X X-FCU. Se hai opinioni diverse, benvenuto a comunicarne di più! Xinling Industry è un'azienda focalizzata sulla fornitura di una gamma completa di soluzioni one-stop per macchine di posizionamento ASM. È stata profondamente coinvolta nel settore delle macchine di posizionamento per 15 anni, fornendo vendite di macchine di posizionamento ASM, leasing, fornitura di pezzi di ricambio, manutenzione delle attrezzature e manutenzione del motore della scheda. , Manutenzione Feida, manutenzione della testina di patch, formazione tecnica di una gamma completa di attività!