The following is a comprehensive introduction to common faults and maintenance ideas for II-VI Laser SW11377 lasers, which is organized based on the common failure modes of lasers and the technical characteristics of II-VI (now Coherent) related products:

1. Overview of II-VI Laser SW11377

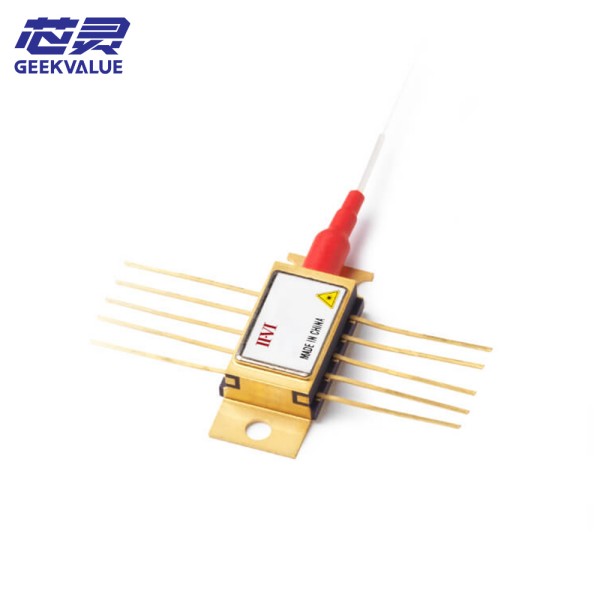

II-VI (now merged into Coherent) lasers are widely used in industrial processing, medical treatment, scientific research and semiconductor manufacturing. SW11377 may belong to the short-wave infrared (SWIR) laser module or high-power semiconductor laser series. Its typical applications include:

3D sensing (such as AR/VR, autonomous driving LiDAR)

Material processing (micro welding, precision cutting)

Medical equipment (laser therapy, optical imaging)

2. Common faults and maintenance ideas

(1) Laser output power decreases or no output

Kemungkinan alasan:

Laser diode aging (long-term high-power operation leads to light decay)

Power supply failure (unstable power supply, filter capacitor damage)

Optical component contamination (dust and oil affect beam transmission)

Ide pemeliharaan:

Check the power supply: Use a multimeter to measure the input/output voltage to confirm whether the power module is normal.

Clean the optical path: Use dust-free lens cleaning paper + anhydrous alcohol to clean the laser output window, reflector and other optical components .

Replace the laser diode (if confirmed to be aging, professional replacement is required).

(2) Laser overheat alarm

Kemungkinan penyebabnya:

Cooling system failure (water pump/fan stopped, coolant leaked)

Radiator blocked (dust accumulation affects heat dissipation efficiency)

Ambient temperature is too high (outside the operating temperature range)

Ide pemeliharaan:

Periksa sistem pendingin:

Confirm whether the coolant is sufficient and whether the pipes are leaking.

Test whether the cooling fan/water pump is operating normally.

Clean the radiator: Use compressed air to remove dust.

Optimize the working environment: Ensure that the equipment operates in an environment of 10°C–35°C4.

(3) Beam quality deteriorates (increased divergence angle, uneven spot)

Kemungkinan penyebabnya:

Optical component offset or damage (such as loose collimating lens)4

Laser diode mode deteriorates (long-term use leads to unstable beam mode)

Ide pemeliharaan:

Recalibrate the optical path: Adjust the position of the lens and reflector to ensure beam collimation.

Replace damaged optical components (such as lens coating damage).

(4) Control system failure (failure to start or abnormal communication)

Kemungkinan penyebabnya:

Control board damage (liquid infiltration, electrostatic breakdown)

Software failure (firmware crash, parameter setting error)

Ide pemeliharaan:

Check the control board:

Observe whether there are obvious damages such as burn marks, capacitor bulging, etc.

Use a multimeter to detect whether the key circuit is short-circuited/open-circuited .

Restart/upgrade firmware: restore factory settings or update the latest firmware version.

(5) Laser intermittent operation (sometimes good, sometimes bad)

Kemungkinan penyebabnya:

Poor contact (loose plug, poor soldering)

Power supply fluctuations (unstable power grid or filter capacitor failure)

Ide pemeliharaan:

Use the "knocking hand pressure method": tap the circuit board to observe whether the fault recurs and confirm the poor contact point .

Replace the filter capacitor: If the power output is unstable, check and replace the aging capacitor .

3. Preventive maintenance recommendations

Clean the optical components regularly (once a month to avoid dust accumulation).

Monitor the cooling system (check the coolant and cooling fan every quarter).

Avoid overload operation (no more than 80% of the rated power for long-term use).

Anti-static measures: Wear an anti-static wristband during operation to avoid circuit board damage.

4. Kesimpulan

Common faults of II-VI Laser SW11377 are mainly concentrated in laser output, cooling system, optical path calibration and circuit control. Maintenance requires power detection, optical path cleaning, hardware replacement and other methods. For complex faults, it is recommended to contact our technical department to avoid self-disassembly and further damage.