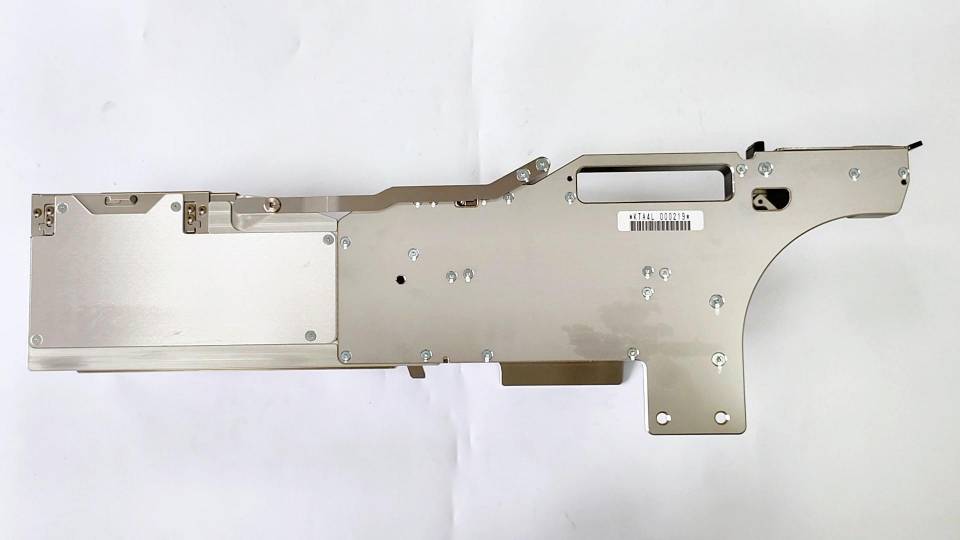

Fungsi utama pengumpan mesin SMT Fuji 104MM adalah untuk digunakan dalam produksi SMT (teknologi pemasangan permukaan), untuk mengeluarkan komponen selebar 104MM dari baki dan menempatkannya secara akurat pada papan PCB. Ini adalah bagian penting dari mesin SMT dan secara langsung memengaruhi kualitas dan efisiensi produksi SMT.

Metode pemeliharaan dan perawatan

Untuk memastikan pengoperasian normal dan keakuratan pengumpan mesin SMT Fuji 104MM, diperlukan perawatan dan pemeliharaan rutin:

Bersihkan pengumpan secara teratur: singkirkan debu dan bulu halus untuk mencegah debu menumpuk di slider dan perlengkapan pengumpan serta bagian lainnya, yang memengaruhi akurasi.

Pengisian bahan bakar secara teratur: lumasi bagian-bagian penting untuk mencegah peningkatan gesekan, yang mengakibatkan penurunan akurasi dan peningkatan kebisingan.

Ganti filter sumber udara secara teratur: pastikan sumber udara bersih untuk mencegah kelembapan dan kotoran memengaruhi efek penyerapan nosel.

Periksa komponen secara berkala: periksa berbagai komponen pengumpan untuk memastikan tidak ada kerusakan atau kelonggaran guna memastikan pengoperasian normal pengumpan. Masalah umum dan solusinya

Selama penggunaan, Anda mungkin mengalami masalah dan solusi berikut:

Penutup pengumpan tidak terpasang: Saat memuat, perhatikan apakah penutup terpasang untuk menghindari kerusakan pada nosel.

Komponen berserakan: Jika ditemukan komponen pengumpan yang berserakan pada sumbu Z mesin penempatan, personel pemeliharaan harus segera diberitahu untuk melakukan pemeriksaan.

Kerusakan nosel: Periksa apakah nosel aus atau rusak, dan ganti jika perlu.

Melalui tindakan pemeliharaan dan perawatan di atas, masa pakai pengumpan mesin SMT Fuji 104MM dapat diperpanjang secara efektif untuk memastikan stabilitas dan presisinya dalam produksi SMT.