Pengumpan rol pemotong adalah perangkat untuk menangani material rol, yang terutama digunakan untuk memandu, mengarahkan, meluruskan, mengumpankan, dan memotong material rol. Prinsip kerjanya terutama menggunakan deformasi material ke arah yang berlawanan di bawah tekanan untuk meluruskan material rol, dan mengirim material rol ke perangkat pemotong untuk dipotong melalui perangkat pengumpan.

Komposisi struktural

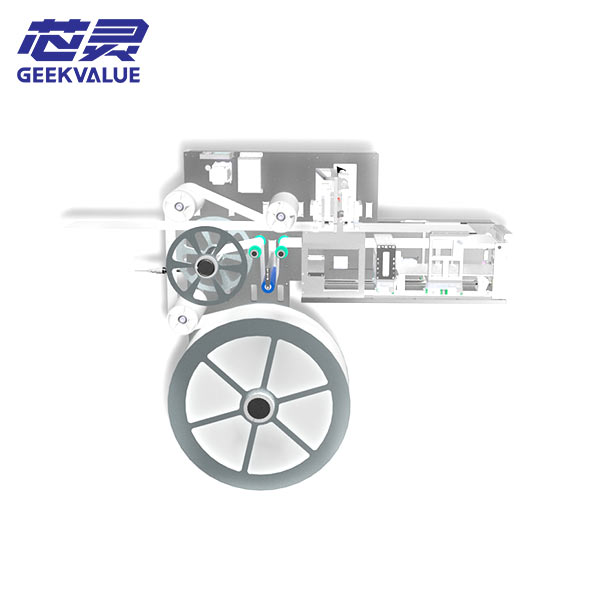

Pengumpan rol pemotong biasanya mencakup komponen utama berikut:

Bahan gulungan pendukung: Memberikan dukungan tertentu untuk bahan gulungan.

Perangkat pengencang: Pastikan bahan gulungan mempertahankan ketegangan yang sesuai selama pengangkutan.

Alat pelurus: Luruskan material rol menggunakan metode "pelurusan berlebih". Mekanisme pelurusan umum meliputi mekanisme pelurusan pelat sisir dan mekanisme pelurusan rol.

Alat pemasukan: Masukkan material rol ke alat pemotong melalui gesekan. Alat pemasukan yang umum termasuk alat pemasukan tuas dan alat pemasukan bola baja.

Alat pemotong: Potong bahan gulungan dengan rapi. Metode pemotongan yang umum meliputi pemotongan mekanis dan pemotongan gabungan dengan alat penyegel panas.

Prinsip kerja

Prinsip kerja pengumpan rol potong terutama mencakup langkah-langkah berikut:

Pelurusan: Gunakan deformasi material pada arah berlawanan yang disebabkan oleh tekanan untuk meluruskan gulungan.

Pengumpanan: Gulungan yang telah diluruskan dikirim ke perangkat pemotong melalui perangkat pengumpanan.

Pemotongan: Gunakan alat pemotong untuk memotong gulungan dengan rapi. Metode pemotongan yang umum termasuk pemotongan pisau terbang dan pemotongan pisau gulung.

Skenario aplikasi

Pengumpan rol pemotong banyak digunakan dalam pemrosesan berbagai bahan rol, termasuk kawat logam, strip logam, kertas, film plastik, kertas label, pita perekat, dll. Pengumpan rol pemotong memiliki berbagai macam aplikasi dan cocok untuk kebutuhan pemrosesan material dalam berbagai produksi industri.

Singkatnya, pengumpan rol potong adalah perangkat yang mengintegrasikan fungsi pelurusan, pengumpanan, dan pemotongan. Perangkat ini cocok untuk pemrosesan berbagai bahan rol dan banyak digunakan dalam produksi industri.