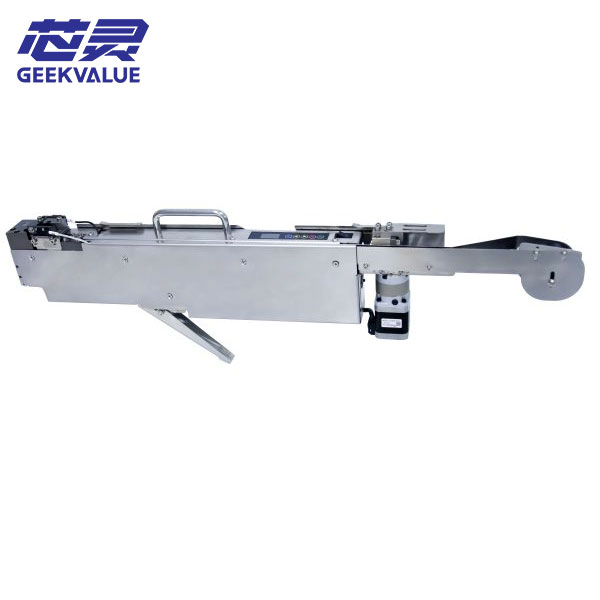

Le chargeur vertical courbé est un dispositif utilisé pour l'alimentation de composants électroniques. Il est principalement utilisé pour envoyer des composants électroniques emballés en bande verticale un par un, couper les fils des broches et les alimenter à la machine enfichable. Ses principales fonctions et caractéristiques comprennent :

Alimentation précise : l'alimentation par moteur est utilisée pour garantir la précision de la position d'alimentation.

Bon effet de coupe des jambes : utilisez le moteur pour couper les jambes et les bavures seront petites après avoir coupé les jambes.

Forte adaptabilité : il peut traiter diverses formes de moulage, de pied en K, de pliage à 90 degrés, de formage en H et d'autres opérations.

Forte compatibilité : il peut être utilisé avec n'importe quelle marque de machine enfichable et convient aux lignes de branchement manuel en ligne.

Petite taille : conception compacte, économisant de l'espace debout.

Améliorer le niveau d’automatisation : Améliorer le niveau d’automatisation des usines des clients.

Scénarios applicables et applications industrielles

Les alimentateurs verticaux de pliage sont largement utilisés dans la production automatisée et le processus de branchement de composants électroniques, et sont particulièrement adaptés aux environnements qui nécessitent une production de haute précision et efficace. Il peut améliorer considérablement l'efficacité de la production et la qualité du produit, et convient à diverses entreprises de fabrication électronique et lignes de production.

Conseils d'entretien et de soins

Afin d'assurer le fonctionnement stable à long terme de l'alimentateur vertical de pliage, il est recommandé d'effectuer régulièrement les opérations de maintenance et d'entretien suivantes :

Nettoyer l’équipement : Nettoyez régulièrement la poussière et les débris à l’intérieur de l’équipement pour garder l’équipement propre.

Vérifiez le moteur : Vérifiez régulièrement l’état de fonctionnement du moteur pour garantir son fonctionnement normal.

Lubrification des pièces : Lubrifiez les pièces mobiles de l'équipement pour réduire l'usure.

Équipement d'étalonnage : Calibrez régulièrement la précision d'alimentation et de découpe de l'équipement pour garantir la qualité de la production.

Grâce aux mesures de maintenance et d’entretien ci-dessus, la durée de vie de l’équipement peut être efficacement prolongée et l’efficacité de la production améliorée.

![4. [Bending] vertical feeder DK-RDD2105 (L) 4. [Bending] vertical feeder DK-RDD2105 (L)](https://www.all-smt.com/uploadfile/202411/32bf588e4a0b4e8.jpg)