Kiire tempoga elektroonikatööstuse maailmas on konkurentsis püsimiseks võtmetähtsusega täpsus, tõhusus ja töökindlus. Kuna nõudlus miniatuursete komponentide, keeruliste trükkplaatide ja suuremahulise tootmise järele kasvab, vajavad tootjad lahendusi, mis lihtsustavad nende protsesse ja vähendavad vigu. Siin avaldavad 3C etiketisööturid märkimisväärset mõju. Need automatiseeritud seadmed muudavad elektroonikatööstuse toodetele märgistamise viisi, pakkudes võrratuid eeliseid kiiruse, täpsuse ja paindlikkuse osas.

Selles juhendis käsitleme 3C-märgisööturite rolli elektroonikatööstuses, uurime nende peamisi eeliseid ja selgitame, miks need tööstust revolutsiooniliselt muudavad.

Mis on 3C etiketisööturid?

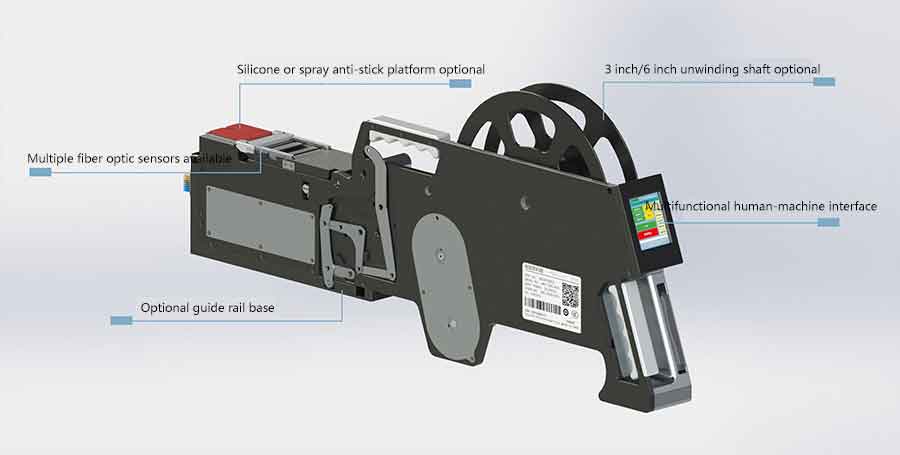

3C etiketisööturid on spetsiaalsed seadmed, mida kasutatakse elektroonikatööstuses toodetele, komponentidele või pakenditele märgistamise protsessi automatiseerimiseks. Need söötjad on loodud käsitsema mitmesuguseid materjale, nagu pabersildid, Mylari teip ja kõrge temperatuuriga sildid. Mõiste "3C" viitab andmetöötlusele, side- ja olmeelektroonikale – kolmele peamisele sektorile, milles neid feedereid kõige sagedamini kasutatakse.

Need söötjad väljastavad ja paigutavad silte automaatselt suure täpsusega, tagades nende kindla kinnituse toodetele tootmisprotsessi igas etapis. Olenemata sellest, kas tegemist on PCB-de (trükkplaatide), nutitelefonide või mõne muu olmeelektroonika märgistamisega, on 3C-märgisööturid saamas tänapäevaste tehaste asendamatuteks tööriistadeks.

Kuidas 3C etiketisööturid parandavad elektroonika tootmist

Suurenenud tootmiskiirus

Üks olulisemaid eeliseid 3C etiketisööturite kasutamisel elektroonikatööstuses on tootmiskiiruse märkimisväärne kasv. Traditsioonilised käsitsi märgistamise meetodid on aeganõudvad ja võivad põhjustada inimlikke eksimusi. Seevastu 3C etiketisööturid automatiseerivad protsessi, võimaldades siltide pealekandmist palju suurema kiirusega, ilma et see kahjustaks täpsust. See toob kaasa läbilaskevõime järsu paranemise, võimaldades tootjatel täita suure nõudlusega tootmiseesmärke ja vähendada konveieri kitsaskohti.

Täpsus ja täpsus

Elektroonikatööstuses on täpsus hädavajalik. Isegi väikseim kõrvalekaldumine võib lõpptootes põhjustada defekte, mis mõjutavad jõudlust ja kvaliteeti. 3C etiketisööturid pakuvad ±0,3 mm söötmistäpsust, tagades, et sildid on paigutatud täpselt sinna, kus neid vaja on. Selline täpsus vähendab märgistamisvigade riski, mis võib säästa aega ja vähendada tootmisprotsessis tekkivaid jäätmeid.

Paindlikkus erinevate materjalide ja suuruste jaoks

3C etiketisööturid on loodud käsitlema mitmesuguseid etiketitüüpe ja -suurusi, muutes need elektroonikatööstuse jaoks uskumatult mitmekülgseks. Olenemata sellest, kas peate kandma väikeseid silte väikestele trükkplaatidele või suuri silte tootepakenditele, sobivad need söötjad erineva paksuse, laiuse ja pikkusega materjalile. See paindlikkus võimaldab tootjatel hõlpsasti vahetada erinevate toodete või pakendikujunduste vahel, ilma et oleks vaja ümbertööriistu või käsitsi reguleerida, vähendades seisakuid ja suurendades tootlikkust.

Inimvigade vähendamine

Käsitöö märgistamise protsessis on vastuvõtlik inimlikele eksimustele, mis võib põhjustada olulisi viivitusi ja toote defekte. Automaatsete 3C etiketisööturitega on selliste vigade tõenäosus minimaalne. Need söötjad on varustatud täiustatud juhtimissüsteemidega, mis tagavad iga sildi täiusliku täpsuse, vältides kulukaid vigu ja parandades toote üldist kvaliteeti.

Kulusäästlik lahendus

Kuigi esialgne investeering 3C etiketisööturisse võib tunduda suur, on selle pikaajaline kokkuhoid märkimisväärne. Suurendades tootmiskiirust, vähendades tööjõukulusid ja minimeerides märgistamisvigadest tulenevaid jäätmeid, aitavad 3C etiketisööturid aja jooksul suurendada tõhusust ja kulutasuvust. Tootjad saavad säästa ka materjalikulusid, vähendades valesti paigaldatud ja kasutuselt kõrvaldatud siltide arvu.

Integratsioon automatiseeritud tootmisliinidega

3C etiketisööturid on loodud integreeruma sujuvalt olemasolevatesse automatiseeritud tootmisliinidesse. Reaalajas tagasisidesüsteemide ja suletud ahelaga juhtimismehhanismidega saab neid sööte sünkroniseerida teiste masinate ja seadmetega, tagades sujuva ja pideva töö. Selline automatiseerituse tase suurendab tootmisprotsessi üldist efektiivsust ja vähendab käsitsi sekkumise vajadust.

3C-märgisööturite rakendused elektroonikatööstuses

3C etiketisööturite mitmekülgsus võimaldab neid kasutada elektroonika tootmise erinevates etappides. Siin on mõned näited nende rakendamisest erinevates sektorites:

Trükkplaadid (PCB-d): märgistamine on oluline PCB-de komponentide tuvastamiseks monteerimise ja katsetamise ajal. 3C etiketisööturid saavad tundlikele elektroonilistele komponentidele automaatselt ja täpselt lisada pisikesi silte.

Nutitelefonid ja kantavad seadmed: olenemata sellest, kas tegemist on QR-koodide, brändilogode või eeskirjadele vastavuse siltidega, aitavad 3C-märgisööturid tagada, et need tooted on õigesti märgistatud ja saatmiseks valmis.

Tarbeelektroonika: alates teleritest kuni helisüsteemideni – 3C sildisööturid lihtsustavad suure tarbeelektroonika märgistamisprotsessi, tagades järjepidevuse ja täpsuse tootmisliinidel.

Pakendamine ja kohaletoimetamine: Lisaks toodete märgistamisele kasutatakse 3C-sööturiid ka saatesiltide, vöötkoodisiltide ja pakendiplommide kinnitamiseks, tagades toodete õige identifitseerimise ja levitamise ajal jälgitavuse.

Miks on 3C etiketisööturid elektroonikatootjate jaoks mänguvahetaja?

3C sildisööturite kasutuselevõtt elektroonikatööstuses kujutab endast paradigma muutust märgistamisülesannete käsitlemisel. Need söötjad mitte ainult ei lihtsusta tootmisprotsesse, vaid suurendavad ka üldist kvaliteedikontrolli, tõhusust ja paindlikkust. Märgistusprotsessi automatiseerimisega saavad tootjad lühendada tootmisaega, minimeerida vigu ja vastata turu kasvavatele nõudmistele.

Kuna elektroonikatööstus areneb edasi ja nõudlus keerukamate toodete järele kasvab, muutuvad automatiseerimislahendused, nagu 3C etiketisööturid, veelgi olulisemaks konkurentsivõime säilitamiseks kiiresti areneval turul. Täiustatud kiiruse, täpsuse ja kulutõhususega muudavad 3C etiketisööturid kahtlemata pöörde elektroonika tootmises.

Kokkuvõtteks võib öelda, et 3C etiketisööturid on elektroonikatööstuses kriitilise tähtsusega tehnoloogia, pakkudes olulisi eeliseid kiiruse, täpsuse ja kuluefektiivsuse osas. Need seadmed on muutnud märgistamisprotsessi revolutsiooniliseks, võimaldades tootjatel toota kvaliteetseid tooteid mastaapselt, vähendades samal ajal vigade ja raiskamise ohtu. Kuna nõudlus automatiseeritud lahenduste järele elektroonikatööstuses kasvab jätkuvalt, on 3C etiketisööturitel tööstuse tuleviku kujundamisel keskne roll.

Investeerides 3C etiketisööturitesse, saavad elektroonikatootjad optimeerida oma tootmisliine, parandada tootekvaliteeti ja lõppkokkuvõttes suurendada oma kasumit. Tänu oma võimele käsitleda erinevaid materjale ja suurusi, integreerimise lihtsust ja ületamatut täpsust muudavad need söötjad tänapäevasel tootmismaastikul kahtlemata muutlikuks.