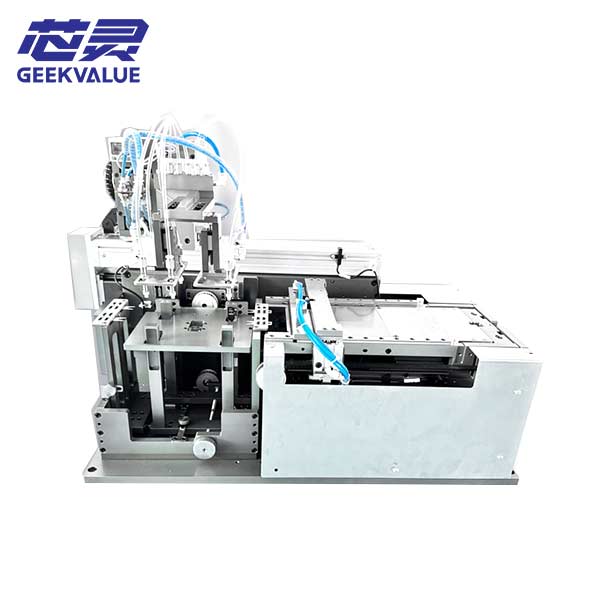

Dies ist ein Front-Push-Blattzuführer, der sich zum automatischen Abziehen und Zuführen von Blattmaterialien wie Papieretiketten, Schutzfolien, Schaumstoffen, doppelseitigen Klebebändern, leitfähigen Klebstoffen, Kupferfolien, Stahlblechen und Verstärkungsplatten eignet. Dieser Zuführer verfügt über ein intelligentes Design in Industriequalität mit hoher Kompatibilität, hoher Zuführgeschwindigkeit und anpassbaren Zuführparametern. Er verfügt außerdem über einen Online- und einen Automatikmodus für den Benutzerkomfort. Er unterstützt die Ausgabe von abnormalen Alarmen und Remote-Reset sowie optionale GPIO-Kommunikation und RS232-Kommunikation. Er unterstützt die einfache Bedienung der Farb-Touchscreen-Anzeigeparameter und die Einstellung von Parametern. Nachdem dieser Zuführer in die Automatisierungsausrüstung integriert wurde, kann er eine automatische Zuführung realisieren und die Produktionseffizienz verbessern. Er eignet sich sehr gut für die SMT-Industrie, die 3C-Fertigungsindustrie und die Logistikindustrie.

Das Funktionsprinzip ist wie folgt:

1. Nehmen Sie das Blattmaterial vom Saugnapf des Blatteinzugs

2. Nachdem Sie das Blattmaterial entnommen haben, legen Sie es auf die vorgesehene Position des Abstreifers

3. Die Materialziehklemme klemmt den leeren Bereich am vorderen Ende des Blattmaterials fest, und der Materialpresszylinder steuert den Materialpressblock, um den leeren Bereich am Ende des Blattmaterials zu pressen

4. Die Saugdüse wird zurück in den Materialbehälter gehoben, um das Material aufzunehmen

5. Die Materialziehklemme zieht das Materialband, um das Material zuzuführen

6. Nach der Zuführung nimmt die Saugdüse das Material ab

(Hinweis: Vor und nach der Zufuhr des Plattenmaterials muss ein freier Bereich von mehr als 25 mm als Klemmposition und Materialpressposition freigehalten werden.)

Wir können nicht nur Standard-Feeder liefern, sondern auch Feeder entsprechend Ihren Materialien und Größen anpassen, um alle Ihre Bedürfnisse zu erfüllen