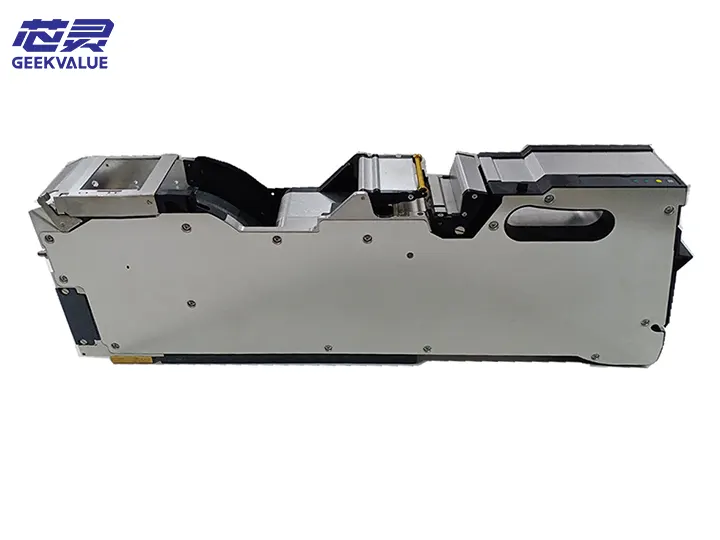

Es eignet sich zum automatischen Abstreifen und Zuführen von Rollenmaterialien wie Papieretiketten, Schutzfolien, Schaumstoffen, doppelseitigen Klebebändern, leitfähigen Klebstoffen, Kupferfolien, Stahlblechen und Verstärkungsplatten. Dieser Feeder verfügt über ein intelligentes Design in Industriequalität mit hoher Kompatibilität, hoher Zuführgeschwindigkeit und anpassbaren Zuführparametern. Er verfügt außerdem über einen Online- und einen Automatikmodus für den Benutzerkomfort. Er unterstützt die Ausgabe von abnormalen Alarmen und Remote-Reset und unterstützt optionale GPIO-Kommunikation und RS232-Kommunikation. Er unterstützt die einfache Bedienung des Farb-Touchscreens zum Anzeigen und Einstellen von Parametern. Nachdem dieser Feeder in die Automatisierungsausrüstung integriert wurde, kann er eine automatische Zuführung realisieren und die Produktionseffizienz verbessern. Er eignet sich sehr gut für die SMT-Industrie, die 3C-Fertigungsindustrie und die Logistikindustrie. Funktionsprinzip: 1. Wenn der Feeder zuführt, muss das Material vollständig abgezogen und ausgegeben werden; 2. Nachdem die Zuführung abgeschlossen ist, saugt die Düse