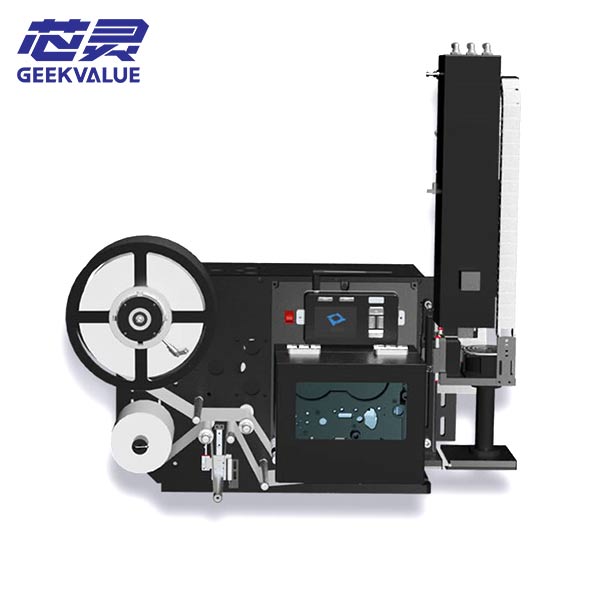

The ASM SMT Label Feeder PN: 030S-B is an advanced and reliable label feeding solution designed to enhance the efficiency and accuracy of automated labeling in SMT (Surface Mount Technology) production lines. This feeder offers impressive compatibility, precision, and durability, making it the perfect choice for industries that require high-volume, high-accuracy label placement. In this article, we’ll explore the key features, advantages, and applications of the ASM SMT Label Feeder PN: 030S-B.

Core Advantages of the ASM SMT Label Feeder

The ASM SMT Label Feeder PN: 030S-B is engineered to meet the most demanding requirements of automated manufacturing, offering several core benefits that set it apart from the competition:

Versatile Material Compatibility: This label feeder is designed to handle a wide range of materials, including paper labels, FPC reinforcing steel sheets, Mylar tape, foam materials, dustproof nets, and high-temperature tapes. Its broad material compatibility ensures that it can adapt to various production environments, from electronics to logistics and packaging.

Flexible Size Handling: The ASM SMT label feeder can accommodate labels of varying sizes within its maximum capacity. Whether you're dealing with small or large labels, this feeder ensures you get the most out of your production line by supporting both single and multiple-row dispensing simultaneously. This flexibility maximizes machine efficiency and reduces downtime.

High-Speed, Accurate Feeding: Achieve precise label placement with ±0.3mm feeding accuracy and an impressive 99.7% discharge rate. This level of precision ensures that your labeling process is consistently accurate, reducing errors and improving overall product quality.

Key Features of the ASM SMT Label Feeder

The ASM SMT Label Feeder PN: 030S-B is built with cutting-edge features that make it an ideal choice for high-speed, automated production lines. Here’s a breakdown of its most important features:

Lightweight, Durable Aluminum Alloy Design: Constructed with high-quality aluminum alloy, the ASM SMT Label Feeder PN: 030S-B is both lightweight and incredibly durable. The solid design ensures that it can withstand the rigors of long-term, continuous use in high-volume production environments without compromising performance.

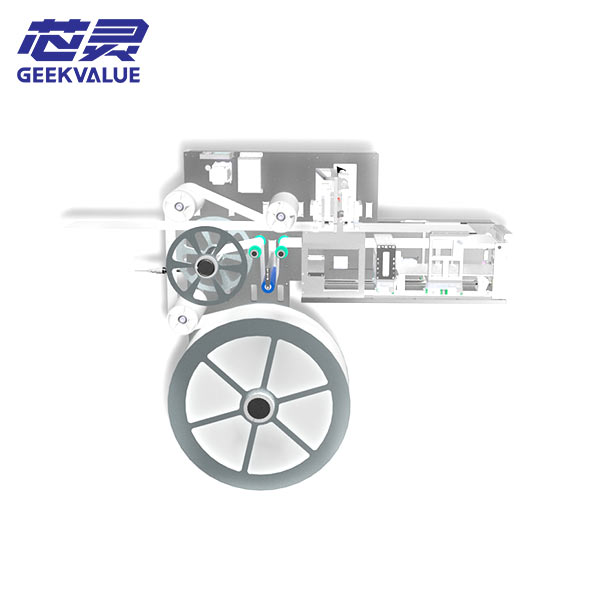

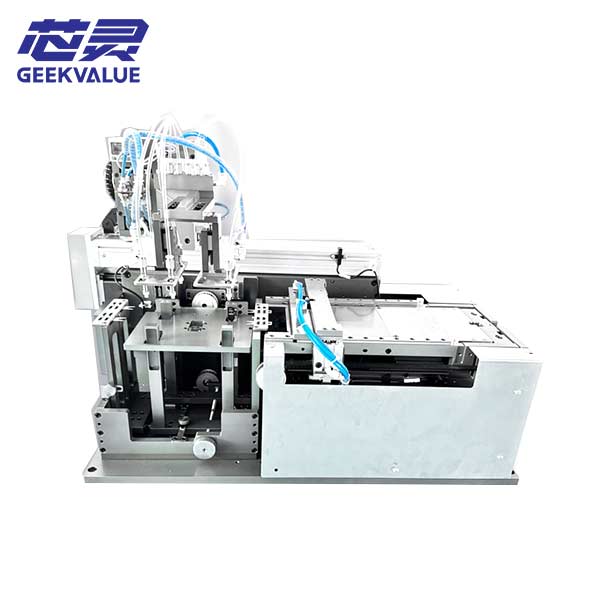

Advanced Push-Feed Technology: Featuring an innovative forward-push feeding mechanism, this label feeder first peels the label from the roll before suctioning it into place. This advanced design improves the feeding process, preventing material jams and ensuring smooth operation even during high-speed production cycles.

Multi-Column Discharge Support: The ASM SMT label feeder is capable of simultaneously discharging multiple rows of labels, making it ideal for handling large batches of materials and improving throughput. This feature is particularly beneficial in mass production settings where time is of the essence.

High Precision and Fast Throughput: With feeding accuracy of ±0.3mm and a discharge rate greater than 99.7%, the ASM SMT Label Feeder PN: 030S-B ensures that labels are fed and applied with exceptional precision, minimizing errors and maximizing output. The high discharge rate means fewer interruptions and more productive hours for your manufacturing processes.

Powerful 32-Bit Processor for Enhanced Control: Equipped with a state-of-the-art 32-bit processor, the ASM SMT label feeder offers superior control performance. The processor allows for real-time adjustments and seamless integration with your existing automated production line.

Closed-Loop Control System: The ASM SMT label feeder utilizes a closed-loop control system, which prevents step losses and dynamically adjusts the output torque during operation. This provides more stable and reliable label dispensing, even under varying production conditions.

Dual Mode Support – Online and Automatic Modes: The ASM SMT label feeder PN: 030S-B offers flexible operation with two modes: online mode for continuous operation and automatic mode for fully automated, hands-off functionality. This adaptability ensures that the feeder can be used in a variety of production scenarios.

Applications of the ASM SMT Label Feeder

The ASM SMT Label Feeder PN: 030S-B is designed to meet the needs of industries that require high-speed, high-accuracy label feeding and attachment. Some of the most common applications include:

Electronics Assembly: Ideal for feeding labels on electronic components, PCBs, and other sensitive items in electronics assembly lines, ensuring that each component is correctly labeled with precision and speed.

Product Packaging: Perfect for industries that require efficient label feeding for products on high-speed packaging lines. Whether you're labeling consumer goods, medical products, or food items, the ASM SMT label feeder ensures that every product is labeled accurately.

Logistics and Shipping: For companies in the logistics industry, the ASM SMT label feeder PN: 030S-B streamlines the process of printing and applying shipping and tracking labels, ensuring accuracy and reducing operational delays.

Product Identification: Whether it’s barcodes, serial numbers, or brand labels, the ASM SMT label feeder can handle various types of product identification, making it essential in sectors like retail, logistics, and inventory management.

Why Choose the ASM SMT Label Feeder

The ASM SMT Label Feeder PN: 030S-B stands out in the market due to its combination of precision, versatility, and high efficiency. Its ability to handle a variety of materials and sizes, combined with its advanced feeding technology and high-speed output, makes it an essential tool for any production line that requires accurate and efficient label placement.

By choosing the ASM SMT label feeder, you’re investing in a reliable, durable, and highly-efficient solution that will improve your production throughput and reduce operational errors, helping you stay competitive in a fast-paced manufacturing environment.

Get in Touch with Us

Want to learn more about how the ASM SMT Label Feeder PN: 030S-B can optimize your labeling process? Contact us today for more details, or request a quote to get started!